Uncategorized

System for Ground Water Remediation at a Power Generation Plant

MAE2 was asked to provide a system based upon detailed written specifications for a Multi Phase Extraction and Groundwater Treatment system. The system is located at a power generation facility.

The detailed specification required that the system be constructed to meet explosion proof NEC Class 1 Division 1 standards. The entire system had to be inspected approved and labeled by MET Labs. The system uses a Busch high vacuum rotary claw pump to extract impacted groundwater and vapors.

The detailed specification required that the system be constructed to meet explosion proof NEC Class 1 Division 1 standards. The entire system had to be inspected approved and labeled by MET Labs. The system uses a Busch high vacuum rotary claw pump to extract impacted groundwater and vapors.

The groundwater is collected in a marine grade aluminum vapor liquid separator and a progressive cavity pump moves the liquids to an oil water separator. Any free product is removed and then a centrifugal pump moves the liquid through liquid phase carbon to treat the dissolved phase gasoline. The system is assembled in an 8’ X 20’ once through land sea container that has been customized with framed interior walls, R13 insulation and a 3200W heater.

Finally, the system will provide run time hours, vacuum trends, and water flow totals recorded through the PLC control panel.

The cellular connection allows full system control and data through easy-to-use web browser access. The instant alarm notification and remote control allows the consultant to immediately respond to any changing site conditions and maximize system run time.

This remediation system uses the following components and subsystems

Rotary Claw Vacuum Pump

PLC Control panel

Bag Filter

Carbon Filtration

Oil Water Separator

Vapor Liquid Separator

Centrifugal Transfer Pump

Progressive Cavity Transfer Pump

Biosparge and SVE Systems Combined to Maximize Site Remediation

MAE2 was approached by a consultant to build a system to remediate Chlorinated Solvents in ground water.

Individual Biosparge and SVE Treatment systems were selected to take advantage of the increased efficiency created by combining technologies.

The site is a manufacturing facility that had a release of chlorinated solvents that impacted the soils and groundwater around the facility, including a creek bed. Bio sparging was chosen to provide a steady volume of oxygen into the soils to support the biodegradation of solvents by the indigenous microbe population. Introducing air flow to the subsurface also helps volatilize the contaminants to increase the efficiency of the Soil Vapor Extraction

The SVE Treatment system was designed to extract vapors that were found in the soils near the manufacturing facility. Six wells vacuum wells were installed and screened at different depths in order to influence the entire plume. The Bio sparge injection wells were designed to inject air into 3-4 well zones and an additional aeration well located in the creek bed.

The SVE System included a 10 HP C10 Rotary Claw Vacuum Blower, capable of 255 ACFM @ 15” Hg, an 80G, marine grade aluminum, vapor liquid separator, and a PLC control panel with wireless telemetry. The remote telemetry can be used to monitor the system remotely and send alarm notifications. The system was installed inside a cargo trailer that fit the consultant’s needs and price points.

The Bio Sparge system included a 10 HP Rotary Screw Compressor capable of 35 CFM @ 150 psi. The compressor automatically cycles between different sparge zones via a user programmable PLC controller. The system was enclosed in a 8’ x 10’ steel frame building with custom duct work, 1’’ foam insulation in the walls and ceilings, and temperature monitoring. The controls for the bio sparge system can be remotely accessed via a wireless modem to assess alarms, site performance, or to monitor and adjust the sparge zone timing.

This Air Sparge System uses the following components and subsystems

Relay Based Control panel

Rotary Claw Vacuum Pump

Integrated Air Sparge System at a Space Launch Center

MAE2 was selected as the most responsive bidder in a competitive bid process to build and start up an integrated Air Sparge system for a former maintenance building at a space launch center.

The system was designed to remediate a solvent plume around the former building site. There are 213 wells spread across the site in order to create high air flow and radius of influence across the plume. The system design includes programmable timers that allow the user to rotate air delivery through the different site areas as desired. There are 10 sparge zones on the site, and each can be programmed for specific on off times to optimize remediation.

The project includes remote operation and monitoring so that the performance can be viewed and adjusted as required. The completed system includes a 125 HP variable speed rotary screw compressor capable of providing up to 648 CFM. The compressor automatically adjusts to provide only the air demand needed at any given moment which saves electricity and prolongs the life of the equipment. The system controls display and log temperature, pressure and CFM flow for the compressor and well field areas. The set points and operation timers can be adjusted remotely by phone or computer to maintain optimum efficiency.

The system was installed in a utility trailer custom designed to handle the size and weight of the compressor. Custom duct-work for compressor the intake and exhaust and split unit air conditioners for climate control were designed to keep the interior of the trailer at the low temperature and low humidity that the compressor requires for proper operation.

The system effectiveness was evident as the influence on the water table and in the monitoring wells was immediate.

This Air Sparge System uses the following components and subsystems

Corrective Action Plan for Former Gas Station Site Remediation

MAE2 was approached by a consultant that had performed a Corrective Action Plan and recommended a multi-phase extraction system to perform remediation at a former gas station site.

In order to keep the budget costs low the consultant looked for a high quality, dependable refurbished system. The consultant wanted a reliable system refurbished with attention to detail and consistent long term product support.

MAE2 bought a used system that had successfully completed remediation and site closure from a consultant in GA. MAE2 brought the system back to our facility and completed a custom refurbishment. MAE2 converted the groundwater pumping/SVE system into a multi-phase high vacuum system. We removed the Positive Displacement Vacuum Blower, Reciprocating Compressor and air and water manifold piping. We installed a Rotary Claw Vacuum Pump and Liquid Carbon Vessels. The system components were completely tested and a full O & M and cleaning was conducted to make the system site ready.

The system is a Dual Phase Extraction and Groundwater Treatment system designed for 20 GPM water flow and 325 ACFM vapor flow at 25” HG. There is a 10 point extraction manifold that pulls both water and vapor from the extraction wells using a 15HP rotary claw vacuum pump. The extracted groundwater is collected in the marine grade aluminum 120 G Vapor/Liquid separator and then pumped to an Oil Water Separator (OWS) using a progressive cavity transfer pump.

Any free fuel that is extracted is collected in the OWS and gravity drains into a product holding tank. The water is pumped from the OWS through a bag filter, to remove suspended solids, and then to a Poly Stackable Tray Air Stripper. After the air stripper the water is pumped through two bag filters in series, to remove any remaining suspended solids and two High Pressure Steel Carbon vessels for final treatment before discharge. The OWS pump and Air Stripper pump are centrifugal transfer pumps. The system is controlled by a custom PLC control panel that allows for remote access and control using web based telemetry.

The reuse of an existing system that is custom refurbished provides a proven cost effective solution and reduces capital costs and delivery time.

Components used in this system

Pilot Test and Startup Support.

MAE2 was contacted by a consultant that needed equipment and support for a high vacuum pilot test.

The contractor wanted to run a pilot test to try to get influence in an area of the site the was dominated by above ground storage tanks and railroad tracks. The soils at the site were very tight, requiring a unit that could operate at vacuum levels 15″ HG and higher. They contacted MAE2 for the pilot test unit and additional on-site support and training.

MAE2 provided a Multi-Phase Vacuum System with a Liquid Ring Vacuum Pump. The Liquid Ring Pump is the best option for vacuum applications that require vacuum levels exceeding 24″ HG. Liquids removed during the pilot test collected in the Vapor Liquid Separator and then were pumped to an on site frack tank. The system was connected to a mobile generator to provide electrical power.

MAE2 provided an on-site technician to help with the set up of the system and generator and training on system operation. The system was connected to a horizontal well that was located under the train tracks and tank farm. The pilot test went well and it proved that high vacuum extraction created the desired air flow and influence.

The following system components were used in the pilot system.

Liquid Ring Vacuum Pump

Vapor Liquid Separator

Progressive Cavity Transfer Pump

PLC Control Panel

Refurbished Dual Phase Extraction and Groundwater Treatment System with Thermal Oxidizer

MAE2 was approached by a consultant that had performed a Corrective Action Plan and recommended a multi-phase extraction system to perform remediation at a gas station site.

The consultant also required a thermal oxidizer to treat the vapors removed from the site. In order to keep the budget costs low the consultant looked for a high quality, dependable refurbished system, along with a rental oxidizer.

The consultant knew from experience that they could rely on MAE2 for quality workmanship and long-term product support.

An existing Dual Phase Extraction system refurbished for this project

MAE2 took an existing Dual Phase Extraction system from our fleet and made minor modifications. The control panel was updated with a new touch screen control panel and remote telemetry system. The system components were completely tested, and a full O & M and cleaning was conducted to make the system site ready.

Existing DPE internal view

The system is a Dual Phase Extraction and Groundwater Treatment system designed for 20 GPM water flow and 330 ACFM vapor flow at 25” HG. There is a 12 point extraction manifold that pulls both water and vapor from the extraction wells using two 10 HP rotary claw vacuum pumps mounted in parallel. The extracted groundwater is collected in the 120 G Vapor/Liquid separator and then pumped to an Oil Water Separator (OWS) using a progressive cavity transfer pump.

Any free fuel that is extracted is collected in the OWS and gravity drains into a product holding tank. The water is pumped from the OWS through a bag filter, to remove suspended solids, and then to a Poly Stackable Tray Air Stripper. After the air stripper the water is pumped through two bag filters in series, to remove any remaining suspended solids and two medium pressure steel carbon vessels for final treatment before discharge. The OWS pump and Air Stripper pump are centrifugal transfer pumps. The system is controlled by a custom PLC control panel that allows for remote access and control using web based telemetry.

Dual Phase Extraction system components

The vapors pulled from the ground contain higher concentrations of hydrocarbon than allowed without treatment. MAE2 provided a rental Gas Fired Thermal Oxidizer to destroy 99+% of the hydrocarbons. The oxidizer uses the hydrocarbons pulled from the ground to fuel the thermal oxidizer, efficiently destroying them.

External Thermal Oxidizer

Components used in this system

Rental Trailer 23815 – High Vacuum Extraction

High Vacuum Extraction Blower Module:

(2) Rotary claw vacuum pump, with a 15 HP 208-230V/3P motor:

- Motor: TEFC (Suitable for CL 1 DIV 2)

- Performance at inlet of blower: 750 SCFM at 22” Hg

- Discharge temperature: 320F at an inlet of 68 F

- Noise rating: 85 dBA

- Integral inlet

- Integral vacuum relief valve

- Air dilution valve with filter silencer

Inlet piping to each blower to contain the following components:

- One (1) 6” Solberg inlet filter/silencer

- One (1) Vacuum gauges

- PVC suction manifold to each of the blowers

Discharge piping from blower to contain:

- 6” SCH40 carbon steel pipe

- Sample port

- Pressure gauge 0-100 IWC

- Temperature gauge, 50-500 Deg F

- Galvanized steel piping to be terminated outside of enclosure with 10’ Aluminum exhaust stack with rain cap (Shipped loose for installation on site by others)

Refurbished Vapor Liquid Separator Module:

AWS-120, 120 G vapor liquid separator with:

- Marine Grade 5052 Aluminum construction

- 4” I/O

- 6” clean out

- Sight glass with column level switch assembly:

- High level alarm switch

- High level pump control switch

- Low level pump control switch

- Manual drain plumbed to exterior of enclosure

Vapor inlet piping to vapor liquid separator to contain:

- Vacuum gauge

- Sample port

- 6” SCH80 PVC piping

Self Priming Centrifugal transfer pump with 2 HP 208-230V/3P motor:

- Performance: Capable of 40 GPM at 10.0 PSIG

- Motor: TEFC (Suitable for CL 1 DIV 2)

Water inlet piping to pump to contain the following components:

- Ball valve

- Wye Strainer

Water discharge piping to contain the following components:

- Pressure gauge

- Sample port

- Gate valve

- Check valve

- 1” SCH80 PVC recirculation line with gate valve

- 2” SCH80 PVC piping to be terminated outside of enclosure

SVE Manifold:

Qty. 1 4” Aluminum SVE Headers with (8) 2” Schd 80 PVC legs for each header, each leg to contain:

- Gate Valve

- Vacuum gauge

- Clear PVC Site tube (12” section)

- 2” FMPT Schedule 80 PVC piping terminated outside of enclosure

Air Sparge Compressor:

One (1) Rotary Claw sparge compressor with 15 HP 230/460V/3P motor

- Motor: TEFC (Suitable for CL 1 DIV 2)

- Performance: 165 CFM at 20 PSI

- Discharge temperature: 220F

- Noise rating: 82 dBA

Compressor assembly to contain:

- Pressure Relief Valve

- Inlet Filter

- 2” Galvanized Discharge piping

- 2” Bleed line with silencer/Muffler

- Discharge Gate Valve

- Discharge Pressure Gauge

- Discharge Temperature Gauge

Compressor Heat Exchanger:

- ½ HP 230 volt 1 phase TEFC Motor

- Delta approach of 110 Degree F

- Discharge pressure gauge

- Discharge temperature gauge

- Condensate drain line

- Galvanized steel piping

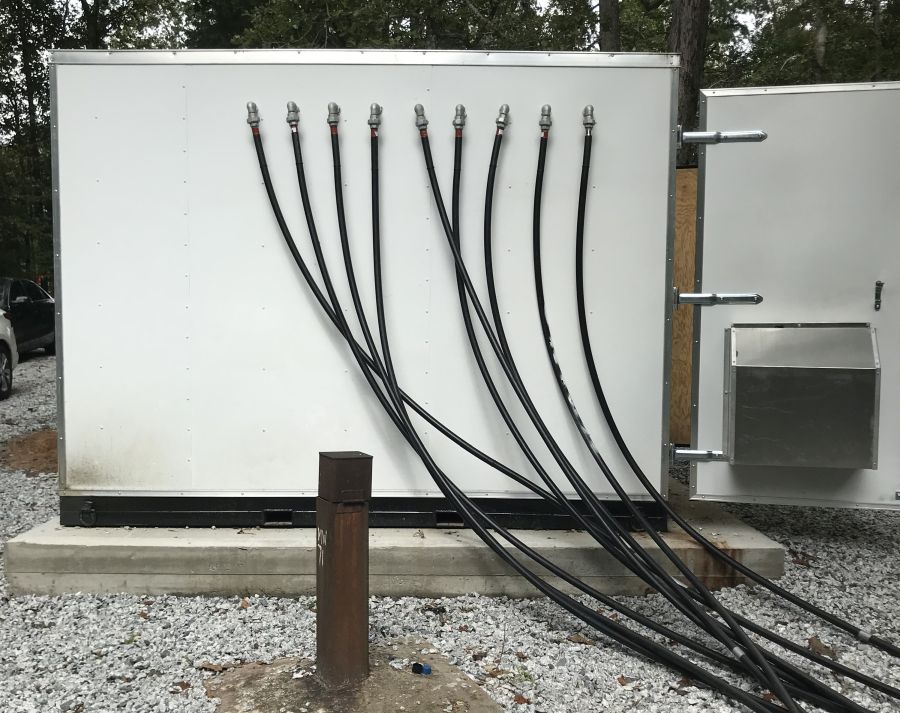

Sparge Manifold: (mounted on exterior trailer wall)

2” Aluminum Sparge Header with (9) 1” Schedule aluminum legs, each leg to contain:

- Ball Valve

- Pressure gauge

- Check Valve

- 1” MPT piping terminated outside of enclosure

Oil Water Separator Module:

Model OWS-40, 40 GPM oil water separator with:

- Designed for oils with a specific gravity of less than 0.90

- 25 micron removal size

- SS Construction

- Gasket sealed lid

- Adjustable rotary skimmer

- Easily removable coalescing media

- Ventilation stack

- Elevated table

- Gravity drain to poly pump out tank

- Sight glass with level switch assembly. Switch assembly to contain:

- High-high level alarm switch

- High level pump control switch

- Low level pump control switch

- Manual drains

Ebara centrifugal transfer pump with 2 HP, 208/230V/3P motor:

- Performance: Capable of 50 GPM at 30 PSIG

- Motor: TEFC (Suitable for CL 1 DIV 2)

Water inlet piping to contain the following components:

- Ball valve

- Wye Strainer

Water discharge piping to contain the following components:

- Pressure gauge

- Sample port

- Gate valve

- Check valve

- 2” SCH 80 PVC piping

Air Stripper Module:

QED 4.4 P Poly Air Stripper

- Four (4) trays

- New York Blower with 3 HP 208-230V/3P motor

- Motor: TEFC (Suitable for CL 1 DIV 2)

- Operational flow rate: 40 GPM

- Max water flow rate: 40 GPM

- Air flow rate: 280 SCFM

- Stripper capable of running continuously or in batch mode

Air stripper tower to contain:

- Sight glass with level switch assembly. Level switch assembly to contain:

- High-high level alarm switch

- High level pump control switch

- Low level pump control switch

- Differential pressure gauge

- Manual drain plumbed to exterior of enclosure

Cleaning Circulation line to contain:

- Ball valves

- Check valve

- 2” PVC SCH80 piping

Ebara centrifugal transfer pump with 2 HP 208-230V/3P motor:

- Performance: Capable of 40 GPM at 30 PSIG

- Motor: TEFC (Suitable for CL 1 DIV 2)

Water inlet piping to contain the following components:

- Wye Strainer

- Ball valve

Water discharge piping to contain the following components:

- Pressure gauge

- Sample port

- Gate valve

- Check valve

- 2” SCH80 PVC piping to be terminated outside of enclosure

- Flow totalizer, 0-50 GPM

Bag Filtration:

- Two (2) number two size bag filter housings in series and parallel with:

- 7” x 36” carbon steel construction

- Pressure gauges

- Ball valves

- Totalizing water flow meter

- Anti-siphon safety valve

Liquid Phase Carbon:

(2) MAE2 model LPHP-500 contactor vessels with:

- Plumbed in parallel

- Max flow rate of 50 GPM

- Pressure rating – 100 PSI

- New Fill of 500 lbs of regenerated liquid phase carbon per vessel

- Pressure gauges

- Sample ports

- Tank Drain

- Isolation Valves

- Three flex hoses (each 15’ in length) with cam lock fittings

Refurbished Remediation Enclosure:

Built to NEC Class 1 Div 2 standards, all wiring intrinsically safe and all equipment pre-piped factory tested and mounted in enclosure

8’ x 28’ x 8’ Cargo Trailer

- 1” sound foam insulated ceiling and walls

- Pressure treat non-skid flooring

- Barn-style rear double doors

- One 36” man door

- Tandem Axle

- Safety Chain

- Running lights

- Break away kit

- Control panel mounted to exterior

Interior to contain the following:

- Vacuum extraction system

- Groundwater treatment system

- Three (3) Lights with the switch outside

- One (1) duplex 15 Amp GFI receptacle

- Ventilation fan with thermostat and hood located near the bottom of the enclosure

- 1.8 kW heater

- Passive vent louvers with sound attenuating hood located near the top of the enclosure

- Emergency stop switch

- All influent, effluent, and drain lines plumbed to outside of building

Refurbished Control System Module:

- Cellular Based Telemetry

- EOS Pro-controller – Remote access through Pro-controller software

- UL certification

- AIC rating of 5000

- NEMA 4 lockable panel enclosure

- Inner swing panel

- Surge and lightning protection for control system

- Main power block

- Motor starters with overload protection

- 24 VDC IS power supply

- Intrinsically safe barriers

- Hour meters for SVE blowers

- One (1) duplex 15 Amp GFI receptacle

- Wired and installed

- Factory tested prior to shipping

Outside cover of inner swing panel to contain the following:

- HOA switches with green run lights

- Red alarm indicator lights

- Alarm reset button

- Hour meters

- Emergency shutdown button

- 250 AMP separate service panel with main and branch circuit protection

Rental Trailer 21611 – Dual Phase Extraction System

DPE Vacuum Pump

Includes: Rotary Claw Blower Package with 15 HP 208-230/3P TEFC motor:

- Maximum performance at inlet of blower: 320 ACFM @ 20” Hg

- 3” inlet/outlet

- Inlet vacuum relief valve (factory set)

Inlet piping to blower to contain:

- 3” Inline Filter MAE2 300T with 234P Filter element

- Vacuum Gauge 0-30” Hg stainless steel liquid filled brass internals

- ¼” Brass Sample Port

- 2” Dilution Filter Solberg FS31P-200 with 2” adjustable brass gate valve

- 3” schedule 80 PVC piping

Discharge piping from blower to contain:

- Pressure Gauge 0-100” wc

- ¼” brass Sample port

- 3” aluminized stack through roof with rain flapper cap

Moisture Separator

Includes: 120 G vapor liquid separator with:

- Aluminum construction

- 8” Clean out with steel pipe plug cover plate

- 3” Inlet/3” outlet

- Vacuum Gauge 0-30” hg Stainless Steel liquid filled with brass internals

- Tank manual drain valve 1/2” brass ball valve

- 2” clear PVC sight tube with 1” Schd 80 PVC TUB ball valve connections

- Stainless steel stem mounted level assembly with union end connection

- LSHH High level alarm switch

- LSH High level pump control switch

- LSL Low level pump control switch

Manifold

Includes: 3” aluminum header with 11 2” legs each with:

- 2” brass gate

- Vacuum Gauge

- ¼” brass sample port

Moisture Separator Effluent Pump

Liquid discharge piping from vapor liquid separator to contain:

- 1” Brass pump inlet ball valve

- 1” brass wye strainer

- Progressive Cavity transfer pump with 1.5 HP 208-230/3P TEFC motor:

- Performance: 10 GPM at 15” Hg

- Discharge Pressure gauge Liquid Filled Stainless 0-100 psi

- ¼” Brass Sample port

- 1” brass discharge gate valve

- 1” brass discharge swing check valves

- 1” Schd 80 PVC piping

- 1” recirculation line with gate valve

- Pump to be closed coupled and mounted on elevated base

Oil Water Separator

Includes: One (1) OWS-10 with:

- Marine Grade Aluminum construction

- Meets or exceeds API 421

- Designed for oils with a specific gravity of less than 0.85

- 25 micron removal size

- Removable, gasket sealed lid

- Adjustable rotary product skimmer with 2” Brass ball valve

- Easily removable PVC coalescing media

- Separation chamber Ventilation stack to exterior of system

- Effluent Pump out Sump

- ½” tank drain valves

Product Drum:

- 55 Gallon Closed Top Steel Drum (shipped Loose)

- Single Point Stainless Steel Float switch with High Level alarm

- Float stem wiring to junction box mounted to exterior of system by others

Oil Water Separator Effluent Pump

Liquid discharge piping from vapor liquid separator to contain:

- 1” Brass pump inlet ball valve

- 1” brass wye strainer

- SS centrifugal transfer pump with 3/4 HP 208-230/3P TEFC motor:

- Performance: 10 GPM at 50 TDH

- Discharge Pressure gauge Liquid Filled Stainless 0-100 psi

- ¼” Brass Sample port

- 1” brass discharge gate valve

- 1” brass discharge swing check valves

- 1” Schd 80 PVC piping

- Pump to be closed coupled and mounted on elevated base

Air Stripper

Includes: QED EZ Stacker 2.4 air stripper with 3HP Blower 208-230/3P TEFC motor

- Max water flow rate: 25 GPM

- Air flow rate: 140 SCFM @ 24” wc pressure

- 1/2” drain with brass ball valve

Air supply piping to stripper to contain:

- Sump Differential Pressure gauges (2) 0-100” wc

- Pressure Switch 0-40” wc with Low adjustable alarm settings

- Blow Discharge Butterfly Valve 4” Lug Style with Flanged ends

- 4” Inlet plumbed to exterior of system enclosure

- PVC piping

Air discharge piping from air stripper to contain:

- 4” PVC piping exit through wall with PVC Tee rain cap 3’ above roof-line

Air Stripper Effluent Pump

Liquid discharge piping from vapor liquid separator to contain:

- 1” Brass pump inlet ball valve

- 1” brass wye strainer

- SS centrifugal transfer pump with 1 HP 208-230/3P TEFC motor:

- Performance: 10 GPM at 60 TDH

- Discharge Pressure gauge Liquid Filled Stainless 0-100 psi

- ¼” Brass Sample port

- 1” brass discharge gate valve

- 1” brass discharge swing check valves

- 1” Schd 80 PVC piping

- Pump to be closed coupled and mounted on elevated base

Bag Filtration

Two (2) BNF-1 # 1 size carbon steel filter housings with:

- Plumbed in Parallel with (4) 1” Brass inlet/outlet isolation ball valve

- 12 size filter vessels

- Inlet/Outlet liquid filled stainless steel 0-100 PSI pressure gauge

- 1” side inlet/side outlet schedule 80 pvc piping

- Swing Bolt Cover

- Stainless Steel Strainer Basket

- Adjustable Tripod Leg Stand

- ¼” Bleeder valve

- 1/2” Bronze manual drain valve

Liquid Phase Carbon:

Includes: Two (2) MAE2 LDS-100 100 lb. fiberglass Liquid GAC Vessels each with:

- 100 lb. fill of Carbon

- Inlet liquid filled stainless steel 0-100 PSI pressure gauge

- Outlet ¼” brass sample ports

- 3 7’ section of 1” Tiger Flex Chemical hose with Fem Cam Ends

- 1” Schd 80 PVC discharge piping to contain Watts Anti Siphon valve

- Discharge Water meter Dwyer WMT 1” cold water meter

Control System

Includes: PLC Based control panel with the following standard features:

- 230 V 3 phase 4 wire

- UL certification 698A labeled

- NEMA 4 door in door panel enclosure

- Primary circuit protection using through door main disconnect

- Branch Circuit protection for motor & house loads

- Automation Direct Click PLC fully programmed and developed

- (5) Motor starters

- 15 AMP GFI

- Illuminated HOA switches

- Estop Button mounted to exterior of enclosure

- Intrinsically Safe Relays

- Alarms with interlocks for proper system operations

- Automatic restart on power failure

- Phase/Voltage monitor with adjustable trip and restart delays

- Surge and lightning protection via Main Line TVSS

- 9” Color OIT with developed graphics P&ID display

- Hour meters on OIT

- Sixnet 4G wireless modem w/ remote access to system ($125 per month)

- Wired and installed

- Factory tested prior to shipping

Remediation Enclosure

Enclosure Built to NEC Class 1 Div. 2 standards for DPE room. All wiring Class I Div. 2 wiring will be intrinsically safe.

All equipment will be pre-piped, pre-wired, mounted and factory tested in enclosure

Includes: 8’ x 18 x 7.6’ enclosed cargo trailer with the following standard features:

- (2) spring axles

- 4 D rings welded to trailer corners for tie down purposes

- 3/8” interior plywood walls and ceilings

- 1” insulation in walls and ceilings

- ¾” pressure treated plywood floor with anti skid paint

- Steel tube frame 16” on center walls and 24” on center ceilings

- Double rear locking doors

- 36” man locking man door

- .24 white exterior aluminum siding

- Galvalume steel roof with high tech sealant

- Electric Breaks with breakaway switch, 2 5/16 coupler with safety chains

- DOT triple rear sealed lights, signal lights and reflectors

- Front stone guard, aluminum exterior trim and fenders

Interior to contain

- DPE Blower, Knockout, OWS, Air stripper, Carbon, Pumps & DPE Piping

- Control panel to be mounted on front wall of trailer

- 16” EXP ventilation fan with 16” intake louver with remote T stat

- 36 Kw EXP heater with remote T stat

- Fan and Intake Rain hoods

- (2) wall mount 20” air intake louvers with Rain hoods

- E stop Box near door Circuit to be Intrinsically Safe (Class I Div. 2)

- Pipe penetration sealed with high temp caulk

- All influent, effluent lines plumbed through trailer floor

Rental Trailer 13410 – DPE System

SVE Influent Manifold

Includes: 4” Header and Nine (9) 2” individual legs each leg to contain:

- 2” ball valve

- 0-30” Hg vacuum gauge

- 2” PVC SCH80 plumbing for influent manifold

Rotary Claw MPE Vacuum Pump

Includes: Two (2) Rotary claw vacuum pumps with 7.5 HP 230/460V/3P motor:

- Motor: TEFC (suitable for Class 1 DIV 2)

- Maximum performance at inlet of each blower:

- 338 ACFM @ 20” Hg (116 SCFM)

- Expected inlet pressure losses through MAE2 system: 15” WC

- Noise rating: 82 dBA

Inlet piping to blowers to contain:

- Vacuum gauges

- 2” Inlet gate valves

- 2” Discharge check valves

- One (1) 4” Solberg inlet filter/silencer

- One (1) 2” Dilution valve with Solberg filter/silencer

- One (1) Auto Oiler

- PVC piping

Common Discharge piping from blowers to contain:

- Sample port with gate valve

- Pressure gauge

- Temperature gauge

- Steel piping

Moisture Separator

Includes: 120 G vapor liquid separator with:

- Aluminum Construction

- 4” inlet

- 6” clean out

- 2” clear PVC sight tube

- Stainless steel stem mounted level assembly

- High level alarm switch

- High level pump control switch

- Low level pump control switch

- Manual drain plumbed to exterior of enclosure

Moisture Separator Effluent Pump

Liquid discharge piping from moisture separator to contain:

- Ball valve

- 2 HP 230 V 3 phase TEFC Progressive cavity transfer pump:

- Performance: 25 GPM at 15” Hg

- Pressure gauge

- Sample port

- Gate valve

- Check valve

- Re-circulation line

- PVC piping

OIL WATER SEPARATOR/AS COMBO UNIT

MAE2 10 GPM oil water separator with:

- Designed for oils with a specific gravity of less than 0.75

- 25 micron removal size

- Gasket sealed lid

- Adjustable rotary skimmer

- Easily removable coalescing media

- Ventilation stack

MAE2 Diffuser Stripper Box with:

- 2” Gravity inlet

- 2 2” PVC Diffuser Tubes

- Effluent Pump out tank

- Effluent chamber high level alarm switch

- Effluent chamber high level switch

- Effluent chamber low level switch

- Manual drains

Centrifugal transfer pump:

- Motor: 1 HP 230 V 3 phaseTEFC (Suitable for CL 1 DIV 2)

- 25 GPM @ 50 TDH

Water inlet piping to contain the following components:

- Ball valve

- Wye Strainer

Water discharge piping to contain the following components:

- Pressure gauge

- Sample port

- Gate valve

- Check valve

- PVC piping

Diffuser Blower

Includes: Air supply piping to stripper to contain:

- 3 HP 230 V 3 phase pressure blower 210 cfm @ 14” wc

- Inlet filter screen

- Pressure gauge

- Butterfly valve

- Pressure gauge

- Low pressure alarm switch

- PVC piping

Air discharge piping from air stripper to contain:

- Sample port

- PVC piping to be piped through roof of enclosure

Air Stripper Effluent Transfer Pump

Water discharge piping from air stripper to contain:

- Ball valve

- 2 HP 230 V 3 phase Centrifugal transfer pump with:

- Performance: 25 GPM at 90 TDH

- Pressure gauge

- Sample port

- Gate valve

- Check valve

- PVC piping

Bag Filtration

Includes:Two # 2 size bag filter housings with:

- Carbon steel construction

- 2” side inlet/bottom outlet

- Tripod stand

- Pressure gauges

- Ball valves

- Sample ports

- Set of 2” chemical hose with cam lock ends

Carbon Filtration

Includes: Two 200 lb liquid phase carbon vessels with:

- FRP construction

- 1” side inlet/bottom outlet

- Interconnecting hose with cam/groove fittings

- Pressure gauges

- Ball valves

Control System

Includes: PLC based control panel with the following standard features:

- NEMA panel enclosure

- Externally mounted Emergency Stop/Disconnect Switch

- Inner swing panel

- Primary circuit protection using internal fused main disconnect

- Main power block

- Branch circuit protection with circuit breakers for motors

- Motor starters with overload protection

- Branch circuit protection with circuit breakers for powered devices

- PLC control system

- Wireless modem telemetry (requires $125 per month service fee)

- 9” Color Operator interface with graphics

- 24 VDC IS power supply

- Intrinsically safe relays

- Wired and installed

- Factory tested prior to shipping

Outside cover of inner swing panel to contain the following:

- HOA switches with green run lights

- Red alarm indicator lights

Remediation Enclosure

Built to NEC Class 1 Div 2 standards, all wiring intrinsically safe and all equipment pre-piped factory tested and mounted in enclosure

Includes: 8’ x 24 enclosed cargo trailer with the following standard features:

- 7.5’ standard interior height

- Tandem axles

- Aluminum siding (white)

- Independent suspension

- Electric brakes

- Break away kit

- Safety chain

- Insulated walls and ceiling

- Barn-style rear double doors

- One man door

- Control panel mounted to exterior

Interior to be rated hazardous and to contain the following:

- Vacuum extraction system

- Groundwater treatment system

- EXP Lighting

- EXP Ventilation fan with thermostat and sound hood

- Passive vent louvers with sound attenuating hood

- EXP Heater with thermostat controls

- Emergency stop switch

- All influent, effluent, and drain lines plumbed to outside of building

Rental Trailer 23520 – Vapor Liquid Separator

Vapor Liquid Separator

Includes: 80 G vapor liquid separator with:

- 4” inlet and outlet

- Aluminum construction

- 6” clean out

- 2” clear PVC sight tube

- Stainless steel stem mounted level assembly

- High High level alarm switch – discrete input

- Manual drain

SVE Vacuum Blower

Includes:

- One Ohio Medical C10 rotary claw vacuum pump with 10HP 230/460V/3P EXP motor:

- Discrete output

- Max Performance at inlet of blower: 242 ACFM and 21.5” Hg

- Noise rating: 85 dBA

Inlet piping to blower to contain:Vacuum gauge

- Adjustable Vacuum relief valve

- One (1) 4” Solberg inline filter/silencer

- 2” Dilution valve with Solberg filter/silencer

- Sample Port

- 4” SCH80 PVC piping

Discharge piping from blower to contain:

- Discharge Silencer

- Sample port

- Pressure gauge

- Temperature gauge

- 4” SCH40 Steel piping

Remediation Enclosure:

Built to NEC Class 1 Div 2 standards, all wiring intrinsically safe, all equipment pre-piped, factory tested and mounted in enclosure

- 6’ x 6’ Custom steel frame building with the following standard features:

- Aluminum siding

- Plywood floor

- Interior sound insulated walls and ceiling

- Interior painted plywood

- Double man doors

- Sound attenuating insulation

- Control panel mounted to outside wall

Interior to contain the following:

- Vacuum extraction system

- Exp Lighting

- EXP Ventilation fan with on/off switch and sound attenuating hood

- Passive vent louvers with sound attenuating hood

- All influent, effluent, and drain lines plumbed to outside of building

Relay Control Panel

- Control enclosure, NEMA 4, door-in-door

- Main circuit breaker, 230V, 3-pole

- Circuit breakers, 230V, 3-pole, for motor short circuit

- Circuit breakers, 120V, 1-pole

- Motor contactor with adjustable overload relay

- Push button, ESTOP

- Push button, reset

- Selector switch, 3-position, illuminated, HOA

- Run time meter

- Pilot lights, red, 120V

- DC power supply

- IS relay, dual channel

- Timing relay, on delay

- Lot of control relays, terminals, etc.

- UL508A listed

- 20 Amp GFCI outdoor outlet