Filtration Vessels

MAE2 provides a variety of standard design vessels to handle flow rates between 10-2,500 GPM and pressure rating ranging from 75-600 psi. All filter bag/strainers vessels are designed with a recessed basket and a 304 stainless steel strainer basket. Standard vessels are constructed from the highest quality carbon steel, 304 or 316 stainless steel and conform to ASME code standards.

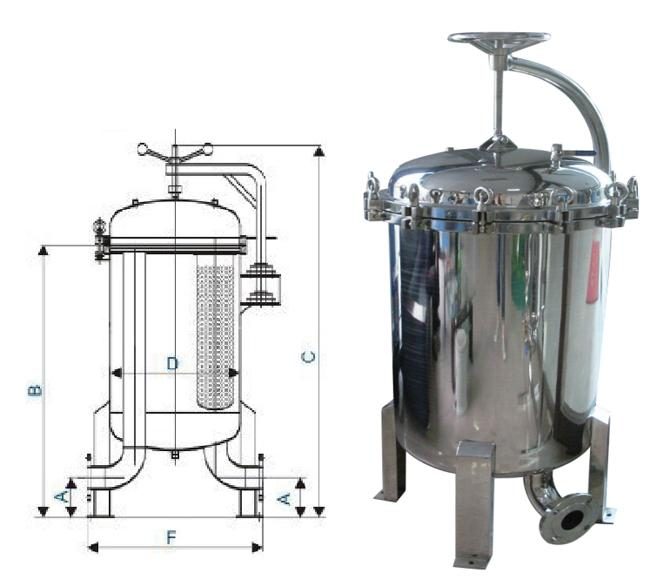

Filter Bag/Strainer Vessels

MAE2 provides a variety of standard design vessels to handle flow rates between 10-2,500 GPM and pressure rating ranging from 75-600 psi. All filter bag/strainers vessels are designed with a recessed basket and a 304 stainless steel strainer basket. Standard vessels are constructed from the highest quality carbon steel, 304 or 316 stainless steel and conform to ASME code standards.

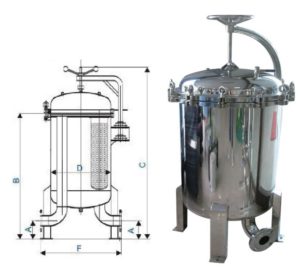

Multi-Bag/Cartridge Filter Vessels

Multi-bag/Cartridge vessels offer large surface areas capable of handling up to 4800 gpm in a single housing. Increasing surface area allows for longer processing time prior to filter change-out. Containing anywhere from 2 to 24 baskets in a single vessel which offers the greatest flexibility and doesn’t require a platform to be built in order to change-out or clean the filter elements or strainers.

Click for downloadable PDF of MAE2 Bag Filtration Datasheet

Sand/Media Filter

Media filters can be designed for a wide variety of solids. Typical media choices include Anthracite for course solids removal, Birm media for removal of Iron and Manganese, Filter-Lite/Sand for removal of suspended solids. These media can be installed in standard pressure vessels and designed with automatic backwashing features.

Click for downloadable PDF of MAE2 Filtration Media Datasheet