Biosparge and SVE Systems Combined to Maximize Site Remediation

MAE2 was approached by a consultant to build a system to remediate Chlorinated Solvents in ground water.

Individual Biosparge and SVE Treatment systems were selected to take advantage of the increased efficiency created by combining technologies.

The site is a manufacturing facility that had a release of chlorinated solvents that impacted the soils and groundwater around the facility, including a creek bed. Bio sparging was chosen to provide a steady volume of oxygen into the soils to support the biodegradation of solvents by the indigenous microbe population. Introducing air flow to the subsurface also helps volatilize the contaminants to increase the efficiency of the Soil Vapor Extraction

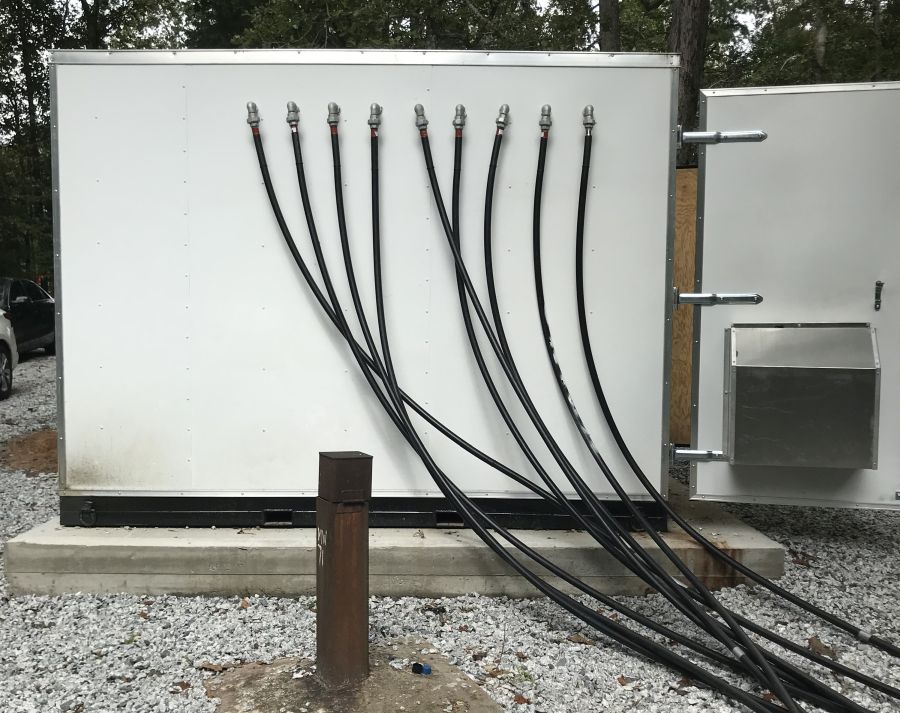

The SVE Treatment system was designed to extract vapors that were found in the soils near the manufacturing facility. Six wells vacuum wells were installed and screened at different depths in order to influence the entire plume. The Bio sparge injection wells were designed to inject air into 3-4 well zones and an additional aeration well located in the creek bed.

The SVE System included a 10 HP C10 Rotary Claw Vacuum Blower, capable of 255 ACFM @ 15” Hg, an 80G, marine grade aluminum, vapor liquid separator, and a PLC control panel with wireless telemetry. The remote telemetry can be used to monitor the system remotely and send alarm notifications. The system was installed inside a cargo trailer that fit the consultant’s needs and price points.

The Bio Sparge system included a 10 HP Rotary Screw Compressor capable of 35 CFM @ 150 psi. The compressor automatically cycles between different sparge zones via a user programmable PLC controller. The system was enclosed in a 8’ x 10’ steel frame building with custom duct work, 1’’ foam insulation in the walls and ceilings, and temperature monitoring. The controls for the bio sparge system can be remotely accessed via a wireless modem to assess alarms, site performance, or to monitor and adjust the sparge zone timing.

This Air Sparge System uses the following components and subsystems

Relay Based Control panel

Rotary Claw Vacuum Pump