Product

Air Sparge System for a Former Heating Plant at a Space launch base

MAE2 was selected after a competitive bid process to build and start up an integrated Air Sparge system for a former heating plant at a space launch base.

The system was designed to remediate a solvent plume and source area at the site of the former heating facility. There are 125 sparge wells spread across the site in order to create high air flow and radius of influence across the plume.

The design required two separate compressors and sparge manifolds. The first compressor was designed for the shallow depth wells and included a refrigerant dryer so that the air supply remained dry and at ambient temperature when leaving the system.

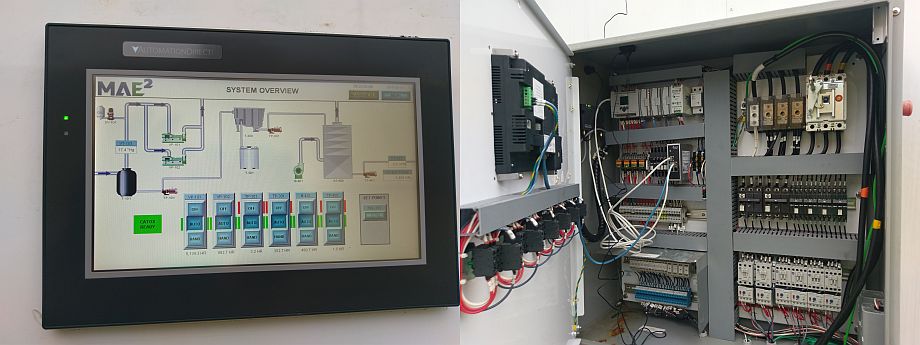

The completed system included a 60 HP variable speed rotary screw compressor capable of providing up to 295 CFM. The compressor automatically adjusts to provide only the air demand needed at any given moment which saves electricity and prolongs the life of the equipment. The system design included programmable timers that allow the user to rotate air delivery through the different site zones as desired. The project included remote operation and monitoring so that the performance could be viewed and adjusted as required.

The System controls display and log temperature, pressure, and CFM flow for the compressor and well field areas. The set points and operation timers can be adjusted remotely by phone or computer to maintain optimum efficiency.

The second compressor was designed for the deeper wells located in the more concentrated source area. The completed system included a 40 HP rotary screw compressor capable of providing up to 215 CFM. This system was piped directly from the compressor through the sparge manifold into the sparge wells. The concept was to use the elevated air sparge temperature of 350 degrees Fahrenheit to optimize source area mobilization and solvent breakdown. The manifold, electric valves, temperature, flow, and pressure transmitters all had to be designed and assembled to withstand the higher temperature of the sparge process air flow.

The systems were each installed in two utility trailers, custom designed to handle the size and weight of the compressors. Custom ductwork and climate control were designed to keep the interiors of each trailer at the low temperature and low humidity that the compressor requires for proper operation. The doors and vent openings on the trailers were also designed to support the compressor operation and maintenance needs.

The Master Control System (MCP) was designed to provide monitoring of the temperature, pressure and CFM flow for the compressor as well as the individual zones going out to the well field. The MCP allows the user to change the set points and zone operation timers to operate in any combination desired for optimum efficiency. Each trailer unit has its own operations control panel which is accessed by the MCP. The MCP was connected to internet based access via a cellular modem allowing for complete system control via any web connected computer or from a smart phone. The password protected remote access provides the same control screens and operational control that you get on site from the MCP.

This Air Sparge System uses the following components and subsystems

Long Term Rental System at a rural GA Gas Station

Rental Systems have often become a preferred option for fund reimbursed cleanup sites.

Renting a system offers flexibility to adapt to site or funding changes. This offers regulators more control over site operations and provides a more predictable reimbursement cost. Also, since rental systems are already assembled, the time from purchase order to start up is much quicker.

The consultant has worked with MAE2 to provide several rental systems for site remediation. The consultant recommended a multi-phase groundwater pump and treat remediation system that incorporated down well groundwater pumps and high vacuum DPE (Dual Phase Extraction) in order to remove the free product and lower the dissolved phase gasoline concentrations.

The consultant has worked with MAE2 to provide several rental systems for site remediation. The consultant recommended a multi-phase groundwater pump and treat remediation system that incorporated down well groundwater pumps and high vacuum DPE (Dual Phase Extraction) in order to remove the free product and lower the dissolved phase gasoline concentrations.

MAE2 provided a high vacuum rotary claw pump system and QED pneumatic auto pumps to dewater the wells and enhance the vacuum influence. The rotary claw vacuum pump was chosen to allow the system flexibility to operate at a wide range of vacuum levels. The flexibility allows the system to operate at low vacuum to help slurp the free product in the wells while pumping at a low rate to maximize the free product recovery. The vacuum can also be increased to maximize dewatering and dissolved phase recovery.

The 9 pneumatic auto pumps operate on demand with a 10 HP reciprocating air compressor providing the air supply needed for pumping. The Groundwater Treatment system consists of an air water separator, an oil water separator to remove free product and a poly stackable tray stripper to remove the dissolved phase gasoline and then pumped through bag filters plumbed in series and two high pressure steel carbon vessels for final treatment before discharge. The OWS pump and Air Stripper pump are centrifugal transfer pumps. An enclosed steel frame utility trailer maximizes flexibility and mobility.

The regulatory agency requires consistent run time for all approved systems. The system provides run time hours, vacuum trends, and water flow totals recorded through the PLC control panel. The cellular connection allows full system control and data through easy-to-use web browser access. The instant alarm notification and remote control allows the consultant to immediately respond to any changing site conditions and maximize system run time.

This Remediation System uses the following components and subsystems

Rotary Claw Vacuum Pump

Poly Stackable Tray Air Stripper

PLC Control panel

Oil Water Separator

Vapor Liquid Separator

Centrifugal Transfer Pump

Progressive Cavity Transfer Pump

Reciprocating Air Compressor

Down well Pneumatic Pumps

System for Ground Water Remediation at a Power Generation Plant

MAE2 was asked to provide a system based upon detailed written specifications for a Multi Phase Extraction and Groundwater Treatment system. The system is located at a power generation facility.

The detailed specification required that the system be constructed to meet explosion proof NEC Class 1 Division 1 standards. The entire system had to be inspected approved and labeled by MET Labs. The system uses a Busch high vacuum rotary claw pump to extract impacted groundwater and vapors.

The detailed specification required that the system be constructed to meet explosion proof NEC Class 1 Division 1 standards. The entire system had to be inspected approved and labeled by MET Labs. The system uses a Busch high vacuum rotary claw pump to extract impacted groundwater and vapors.

The groundwater is collected in a marine grade aluminum vapor liquid separator and a progressive cavity pump moves the liquids to an oil water separator. Any free product is removed and then a centrifugal pump moves the liquid through liquid phase carbon to treat the dissolved phase gasoline. The system is assembled in an 8’ X 20’ once through land sea container that has been customized with framed interior walls, R13 insulation and a 3200W heater.

Finally, the system will provide run time hours, vacuum trends, and water flow totals recorded through the PLC control panel.

The cellular connection allows full system control and data through easy-to-use web browser access. The instant alarm notification and remote control allows the consultant to immediately respond to any changing site conditions and maximize system run time.

This remediation system uses the following components and subsystems

Rotary Claw Vacuum Pump

PLC Control panel

Bag Filter

Carbon Filtration

Oil Water Separator

Vapor Liquid Separator

Centrifugal Transfer Pump

Progressive Cavity Transfer Pump

Rural GA Convenience Store Remediation Site

MAE2 was selected to design and build a Multi Phase Extraction and Groundwater Treatment remediation system for a convenience store site in rural GA.

The consultant was tasked with removing free product which was part of a long narrow plume between the tanks and the gas pump island.

The consultant and MAE2 chose a high vacuum system that could treat extracted groundwater at 15-20 GPM and to remove large amounts of free product gasoline. MAE2 used this data to design a system that would extract and treat groundwater and free product from 6 vacuum wells located on site. The water needed to be treated to meet NPDES limits and was discharged into a roadside ditch.

The system uses 2 high vacuum rotary claw pumps, providing over 500 ACFM flow at 25” HG vacuum, to extract impacted groundwater and vapors. The client prefers to use multiple pumps operating in parallel rather than a single large pump. This design provides more flexibility to save energy as site needs change over time, along with redundancy to reduce downtime. The system uses a 6 point custom inlet manifold and a marine grade aluminum 120 gallon Air Water Separator.

A progressive cavity transfer pump is used to pump the water to a 20 GPM Oil Water Separator to remove any free product gasoline. A 55 gallon drum with a high level alarm is used as a Product Storage Tank. Progressive Cavity pumps are selected because they do not create the chemical emulsification of the gasoline and water that other pumps cause. After the Oil Water Separator removes the free product a centrifugal transfer pump sends the water to a Poly Stackable Tray Air Stripper to remove dissolved phase gasoline. The water is pumped through bag filters, with valves allowing them to be used in parallel or series, to remove solids and particles from the water. Finally the water passes through two Steel High Pressure 250 LB Liquid Carbon Vessels before being discharged to a roadside ditch.

The custom integrated PLC control panel provides runtime hours, vacuum trends, temperature, carbon vessel pressure and water flow totals. The controls use two Variable Frequency Drives (VFD) to convert from 240, single phase power to 240, 3 phase power to operate the system motors.

VFD’s allow users to adjust motor speeds and reduce/save energy. The system uses a cellular data connection allowing full system control and data access through easy to use web browser access. The data allows easy access to system operational status and the data needed for writing reports as required by the regulators.

This Remediation System uses the following components and subsystems:

Interstate Truck Stop Vacuum Enhanced Groundwater Pump and Treat System for Diesel Free Product

MAE2was selected to design and build a remediation system for a large truck stop.

The consultant selected MAE2 to build a vacuum enhanced groundwater pump and treat remediation system that incorporated down well groundwater pumps and high vacuum DPE (Dual Phase Extraction) in order to remove the free product diesel.

MAE2 recommended 3 high vacuum parallel rotary claw pumps capable of 765 ACFM at 15” Hg, along with 7 QED pneumatic auto pumps to remove the free product diesel fuel. The rotary claw vacuum pumps were chosen to allow the system flexibility to operate at a wide range of vacuum levels. The flexibility allows the system to slurp the diesel in the wells to maximize free product recovery. The pneumatic auto pumps operate on demand with a 10 HP reciprocating air compressor providing the air supply needed for pumping. There are custom 6-point air supply and groundwater inlet manifolds for the well pumps.

The Groundwater Treatment system consists of a 15 point custom, marine grade aluminum, inlet manifold a marine grade aluminum, vapor liquid separator, an oil water separator to remove free product, a 270 gallon product tank with high level alarm, 2 bag filters to remove particulates and solids, with valves allowing them to be used in parallel or series, a Poly Stackable Tray Air Stripper to remove dissolved fuel, 2 more bag filters, an Organo Clay media vessel to remove naphthalene, 2 – 500 LB. high pressure steel liquid carbon vessels before discharging to surface water.

A custom modified cargo container was chosen for the project because the size of the components and required space. A cargo container is often exempt from many local building permit requirements

The regulatory agency requires consistent run time for all approved systems. The system provides run time hours, vacuum trends, and water flow totals recorded through the PLC control panel. The cellular connection allows full system control and data through easy-to-use web browser access. The instant alarm notification and remote control allows the consultant to immediately respond to any changing site conditions and maximize system run time.

This Remediation System uses the following components and subsystems:

- Rotary Claw Vacuum Pump

- Removable Tray Air Stripper

- PLC Control panel

- Oil Water Separator

- Vapor Liquid Separator

- Centrifugal Transfer Pump

- Progressive Cavity Transfer Pump

- Reciprocating Air Compressor

- Down well Pneumatic Pumps

- Rotary Claw Compressor

- Liquid Phase Carbon

Integrated Air Sparge System at a Space Launch Center

MAE2 was selected as the most responsive bidder in a competitive bid process to build and start up an integrated Air Sparge system for a former maintenance building at a space launch center.

The system was designed to remediate a solvent plume around the former building site. There are 213 wells spread across the site in order to create high air flow and radius of influence across the plume. The system design includes programmable timers that allow the user to rotate air delivery through the different site areas as desired. There are 10 sparge zones on the site, and each can be programmed for specific on off times to optimize remediation.

The project includes remote operation and monitoring so that the performance can be viewed and adjusted as required. The completed system includes a 125 HP variable speed rotary screw compressor capable of providing up to 648 CFM. The compressor automatically adjusts to provide only the air demand needed at any given moment which saves electricity and prolongs the life of the equipment. The system controls display and log temperature, pressure and CFM flow for the compressor and well field areas. The set points and operation timers can be adjusted remotely by phone or computer to maintain optimum efficiency.

The system was installed in a utility trailer custom designed to handle the size and weight of the compressor. Custom duct-work for compressor the intake and exhaust and split unit air conditioners for climate control were designed to keep the interior of the trailer at the low temperature and low humidity that the compressor requires for proper operation.

The system effectiveness was evident as the influence on the water table and in the monitoring wells was immediate.

This Air Sparge System uses the following components and subsystems

Environmental Remediation System Finds New life at a New Site.

Reuse of an Existing Remediation System results in significant savings and reduced training time.

Many consulting firms have possession of existing remediation systems that have been used to complete the remediation at a site and achieve site closure. Reusing that system on a new site can save cost and increase the bottom line for the consulting firm. Additionally, the field operators are already familiar with the system maintenance and operation. MAE2 has helped many consultants update and refurbish existing systems to help them maximize their resources and provide more competitive solutions to their clients

MAE2 was recently contracted by a consultant to refurbish a used system from their inventory to prepare it and customize it for use at a new site. The refurbished system allowed the consultant to use a system they were familiar with while keeping the budget within approved funding levels.

The system was transported to our manufacturing facility. The MAE2 technical staff thoroughly tested the system and inspected each component. All required maintenance was performed and any components and parts that were beyond their useful life, due to wear and tear, were replaced or upgraded.

The system and controls were customized to meet the requirements of the new site. The end result was a customized, reliable system at a considerable savings when compared to a brand new system. Additionally the consultant’s field staff was already familiar with the system, which greatly reduced labor and training time and costs.

The system is a Dual Phase Extraction and Groundwater Treatment system designed for 10 GPM water flow and 500 ACFM vapor flow at 25” HG. There is a 5 point extraction manifold that pulls both water and vapor from the extraction wells using two 10 HP rotary claw vacuum pumps in parallel. The extracted groundwater is collected in the 120 G Vapor/Liquid separator and then pumped to an Oil Water Separator using a progressive cavity transfer pump. Any free fuel that is extracted is collected in the OWS gravity drains into a product holding tank.

The water is pumped using a centrifugal transfer pump into the Poly Stack-able Tray Air Stripper. The Pressure Blower forces air through the air stripper trays removing over 99% of the dissolved fuel from the water. The water is then pumped through two bag filters in parallel and one high pressure steel carbon vessels for final polishing treatment before discharge. The Air Stripper uses another centrifugal transfer pump to pump the water through the bag filters, carbon and to the final discharge point. The system is controlled by a newly upgraded custom PLC control panel that allows for remote access and control using web-based telemetry.

Components used in this system

Progressive Cavity Transfer Pump

Poly Stack-able Tray Air Stripper

Pressure Blower

CON•FIGURE Modular System

A complete factory-assembled package of a custom designed container for your needs.

The CON•FIGURE Modular System option provides a strong and reliable equipment solution. The CON•FIGURE Modular System is customized to suit each specific project application and reflects experienced and knowledgeable engineering for superior performance and affordable pricing.

Common Applications

Applications include remote project sites, mining and drilling sites, military camps, residential development and resorts. CON•FIGURE offers modular, easily expandable solutions for challenging applications that are remote and located away from needed infrastructure.

Sewage treatment, drinking water, process wastewater from drilling and mining and phased development for remote sites create challenges and barriers that must be resolved for a project to be successful. CON•FIGURE offers low cost, low maintenance packages that can be customized to your needs, and can be installed with minimal site work. The modular shipping container design allows complete flexibility and mobility. It is very easy to expand the capacity as the need increases or to move the CON•FIGURE system to another site if the project ends.

The System

Process Systems Available

CON•FIGURE modular wastewater/sewage systems can be customized to meet your site specific needs and expanded as your operation or community grows.

Typical systems will include an influent settling tank, aeration chamber and Membrane Bioreactor (MBR) filtration. Influent or effluent transfer pumps, Ultra Violet (UV) treatment, Reverse Osmosis (RO), media filtration and sludge dryers can also be added to meet site-specific concerns.

CON•FIGURE process waste water treatment systems typically include chemical pretreatment, settling tanks, oil water separators, sediment filtration, metals separation and media filtration. Ultra filtration, disolved air flotation, mixers and aerators can be added as needed.

CON•FIGURE drinking water systems are designed to meet NSF drinking water standards. Typical systems include influent pumps, settling tanks, Ph adjustment, and media filtration. UV and Ultra filtration can be added as needed.

All CON•FIGURE systems can be customized to include generators, office space and bathroom facilities as needed.

CON•FIGURE systems are designed with user-friendly touch panel controls that make operation easy and provide all performance data and alarm information needed for operation. The control system can be connected using web- based cellular access for remote control and operation.

Designing the Configuration

The CON•FIGURE system is designed to allow for ultimate flexibility and simplicity. MAE2’s approach with our customers is also designed to make your life as simple as possible.

With over 22 years designing integrated treatment systems and controls, MAE2 has the experience and professional staff to help you meet your needs. Whether you have a detailed specification or just an identified need, MAE2 is ready to provide the support and design assistance you desire.

For all CON•FIGURE projects, MAE2 provides:

- Engineering Design Assistance

- Detailed Engineering Drawings

- Carefully Controlled Manufacturing

- Custom Fabrication

- Rigorous Testing Before Delivery

- Unrivaled Customer Support

Unit Features

- Modular for flexible design, assembly and cost savings

- Equipment rooms custom engineered to customer specifications

- Monitoring and testing areas

- Engineered electrical systems

- Engineered mechanical and plumbing, may include courtesy bathroom

- Ease of maintenance

- Secure access

- International Building Code compliant Control and Monitoring Systems

Control and Monitoring Systems

- Custom engineered control packages

- Local main control panels include HMI touch screen display

- Remote communications options include DSL/Cable, Satellite, Wi-Fi, Fiber Optics, GSM Cellular

- Remote diagnostics and reports

Container Options

- Standard 6.5’, 10’, 20’, 40’, 45’, and 53’ ISO Shipping Containers

- Single unit configuration or completely integrated multiple modular units configuration

- Adaptable for environment conditions

- Architectural upgrades include choices for windows, doors, siding, and roof materials

- Air conditioned and insulated spaces (HVAC customizable) Transport and Installation

Transport and Installation

- Standard ISO shipping containers easy to move via truck, rail, ship or plane

- Modular delivery system reduces cost

- Flexible installation

- Basic foundation designs provided

- No specialized construction equipment

- No specialized yard electrical or plumbing needed

Packaged Reverse Osmosis (RO) Water Treatment Systems

Commercial and Industrial RO Systems and Components

Take the expense and the mystery out of large-scale reverse osmosis plants (RO plants) with a packaged system. By making pre-designed, module-sized plants, fully assembled in standard 20-ft and 40-ft containers, the complexity and the construction of a building to house a water purification plant is no longer necessary.

Click the following link to download the RO Brochure

Bio Remediation Systems

Bio Remediation Systems include Aerobic Bioremediation, Anaerobic Dechlorination and Bio Augmentation.

Aerobic Bioremediation Systems

Aerobic Bioremediation Systems are designed to deliver high volumes of dissolved oxygen and hydrocarbon degrading bacteria and nutrients to treat hydrocarbon contaminated sites. The systems provide consistent recirculation of oxygen-rich, nutrient-rich water to provide the critical requirements needed for successful in situ bioremediation. This recirculation provides the appropriate oxygen and nutrient volumes required to degrade the contaminant mass and continuous movement of the amendments throughout the site to provide maximum contact with the contaminated soils. These units can be stand alone or fully integrated into an existing or new Multi Phase Extraction System or Pump and Treat System.

Anaerobic Dechlorination Systems

Anaerobic Dechlorination Systems are designed to deliver substrates and nutrients to create the ideal site conditions for complete dechlorination of TCE, PCE, DCE and VC. The systems provide recirculation of the amended water throughout the site for maximum contact with the contaminated soils. The continuous operation allows for the correct mass delivery, and distribution to prevent biofouling and allow for complete dechlorination without stalling.

Bio Augmentation

Bio Augmentation (biologically enhanced recirculation) involves the injection and recirculation of bacteria, nutrients or substrates to create an active, balanced environment in the subsurface that biologically degrades and eliminates the contamination. MAE2 can help design fully automated and manual recirculation equipment for enhanced Bio remediation for gasoline and chlorinated solvent sites.