Uncategorized

Rental Trailer 22171 – Soil Vapor Extraction System

Soil Vapor Extraction System:

- Roots URAI-DSL 59 rotary lobe blower

- 20 HP 230/460V/3P TEFC motor Operating on a VFD

- 350 SCFM at 10.0” Hg @ 60 Hz

- 175 SCFM at 10.0” Hg @ 30 Hz

- 4” In line particle filter

- Vacuum gauge/Transmitter

- Sample port

- Butterfly valve (suction side carbon)

- Two Tees with caps (suction side carbon)

- 3” Dilution line with filter/silencer and gate valve

- Vacuum gauge

- Ball valve

- Vacuum relief valve

- Pitot tube flow indicator

- PVC piping

Discharge Piping

- Discharge silencer

- Sample port

- Pressure gauge

- Temperature gauge

Moisture Separator

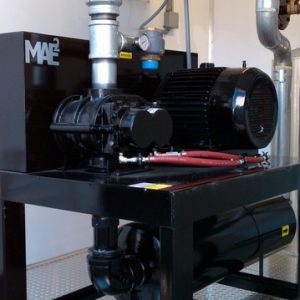

- MAE2 model AW120 marine grade aluminum moisture separator with:

- 4” Inlet/Outlet

- 8” clean out

- Sight glass with high level probe assembly with unions:

- Manual drain

- Vacuum gauge

- PVC piping with the inlet terminated outside of enclosure

SVE Manifold

- 4” header with 5 2” legs each leg with:

- 2” brass gate valve

- Vacuum Gauge 0-30” Hg

- ¼” sample Port

- In Line Rotameter Air Flow Meter

- 2” FMPT process connection for each leg

Air Sparge Compressor:

- Rotary Screw compressor

- 20 HP 230/460V/3P TEFC motor

- 80 SCFM at 100 PSI

- Direct drive

- Integral NEMA 1 control panel

- Integral after cooler

- Air discharge piping from compressor to contain:

- 80 gallon receiver tank with auto-drain

- Particulate filter

- Coalescing filter

- Pressure regulator

- Pressure relief valve

- Temperature gauge

- Pressure Gauge

- Oil/Particulate filters

- Galvanized steel piping

- Solenoid valve

Air Sparge Manifold:

- 1” air sparge discharge manifold constructed with two 1” branches, seven 1/2” legs on one branch and six 1/2″ legs on the other branch to total thirteen

- Each branch to contain:

- Solenoid valve

- Each leg to contain:

- Ball valve

- Pressure regulator

- Pressure gauge

- 2-24 scfm 1/2″ Rotameter style flow indicator with integral needle valve

- Elbow and hose barb turned down 90o

- Galvanized steel piping to terminate outside of enclosure

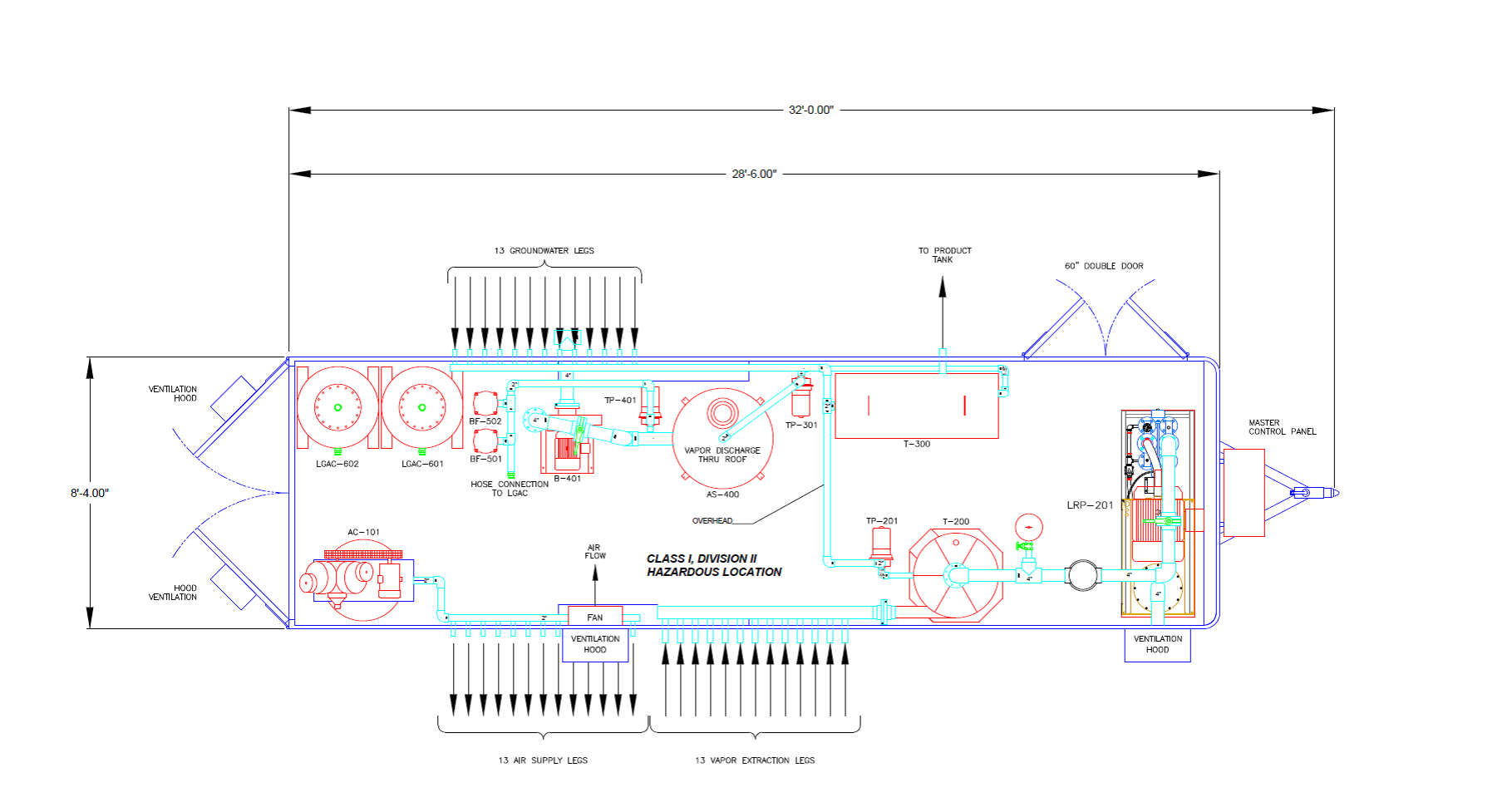

Remediation Trailer:

- One room to be 3rd party inspected, built to NEC Class 1 Div 2 standards, all wiring intrinsically safe and all equipment pre piped factory tested and mounted in enclosure

- One room to be 3rd party inspected, built to NEC General Purpose standards, all wiring complete and all equipment pre piped factory tested and mounted in enclosure

- 8’ x 18’ enclosed, two room cargo trailer with the following standard features:

- 7’ 8” interior height

- Tandem 3500 lbs axles

- Tongue length: 42”

- Aluminum siding (white)

- Independent suspension

- Electric brakes

- Break away kit/Safety chain

- Four jack stands

- Barn-style rear double doors

- One man door located on passenger side of trailer

- 2” Sound attenuating insulation

- Control panel mounted to exterior

- One room to contain the following:

- Vacuum extraction system

- Lighting

- Ventilation fan with thermostat and hood

- Passive vent louvers with sound attenuating hood

- Emergency stop switch

- Non Haz room to contain the following:

- Air sparge system

- Manifold

- Lighting

- Ventilation fan with thermostat and hood

- Passive vent louvers with sound attenuating hood

Controls:

- PLC based control panel with the following standard features:

- UL certification

- EOS with Wireless telemetry including daily reports and alarm notification

- NEMA 4 lockable panel enclosure

- Inner swing panel

- Primary circuit protection using fused main disconnect

- Surge and lightning protection for control system

- Surge and lightning protection for telephone line

- Main power block

- Branch circuit protection with circuit breakers for motors

- Motor starters with overload protection

- 120V/1P power transformer

- Branch circuit protection with circuit breakers for powered devices

- 24 VDC IS power supply

- Intrinsically safe barriers

- Phase monitor

- Timer

- One (1) duplex 15 Amp GFI receptacle

- Wired and installed

- Factory tested prior to shipping

- Outside cover of inner swing panel to contain the following:

- HOA switches with green run lights

- Red alarm indicator lights

- Remote reset of alarms

- Remote shutdown and restart

- Alarm reset button

- Hour meters

- Emergency stop button

- GFI receptacle

Operation And Maintenance Manual:

Operating instructions for all treatment system components Copy of operating manual for each piece of equipment Summary of system components

Summary of system operation principles Summary of operation controls and fail-safes

Summary of maintenance requirements for each piece of equipment

Short Term Rental System for a Groundwater Re-circulation Event at a City Gas Station

MAE2 installed a flexible pump and treat system for groundwater remediation, from our fleet of available rental systems.

MAE2 worked with a consultant who needed a pump and treat system to extract groundwater from two wells and then re-inject the treated water. The project scope called for a 1-week site event and a flexible, and readily available system was required.

Short Term Rental System for a Groundwater Recirculation Event

MAE2 provided an existing trailer mounted system from our fleet and modified it to meet the site specific needs of the short term event. MAE2 fabricated a custom reinjection manifold to make it easy to control the flow into the injection wells. The system components were completely tested before shipping to make certain the system was ready to run on site with no downtime.

The system is a Pump and Treat and Groundwater Treatment system designed for up to 30 GPM water flow. MAE2 provided 2 QED AP4+ Pneumatic Groundwater Pumps complete with downwell air, water discharge and exhaust hoses and well caps.

The system had a Reciprocating Air Compressor connected to an air supply manifold that included pressure and flow controls. Air hose was used to connect the trailer air supply manifold with the downwell pneumatic pumps. The water discharge from the pumps connected to the multi point extraction manifold. The manifold piped the extracted groundwater to an Oil Water Separator to remove any free product gasoline. Any free fuel that is collected gravity drains into a product holding tank. A centrifugal transfer pump sends the water to a Poly Stackable Tray Air Stripper. The Air Stripper removes any dissolved phase gasoline from the water. The water is then pumped through a bag filters in parallel and two high pressure steel carbon vessels for final treatment before discharge.

The pump control allows control of the pressure and flow and the custom fabricated injection manifold allows the user to fine tune the injection volume for each well. The system is controlled by a custom PLC control panel that allows for remote access and control using web-based telemetry.

This Environmental Remediation System uses the following components and subsystems

Reciprocating Air Compressor

Progressive Cavity Pumps

Progressive cavity pumps have a unique design that makes them a good selection for many challenging conditions that are experienced on groundwater remediation sites. Progressive cavity pumps are also called Eccentric Screw Pump which describes the motion and shape of the pump rotor.

The pumps steel rotor presses tightly against the flexible stator creating sealed cavities that progress towards the discharge port with each rotation of the rotor. This progression of the fluid through sealed cavities allows the pump to operate against a high vacuum making it ideal for high vacuum extraction sites.

Unlike other pumps that use impellers to force the fluid forward, the progressive cavity pump does not cause mixing or shearing of the fluid. This makes progressive cavity pumps ideal for sites with free product because the fuel and water remain separated rather than being mechanically emulsified. Emulsified fluids severely reduce the effectiveness of oil water separators, air strippers and even carbon treatment. The progressive cavity design also allows the pumping of suspended solids and viscous fluids without creating the fouling or maintenance issues that limit other types of pumps.

City Convenience Store Environmental Remediation Site

MAE2 was selected to design and build a remediation system for a convenience store site in mixed use city location.

The consultant conducted a multiple day test at the site. The pilot study indicated a need for a high vacuum system that could treat extracted groundwater at 10-15 GPM and to remove large amounts of free product gasoline. MAE2 used this data to design a system that would extract and treat groundwater and free product from 6 wells located on site. The water needed to be treated to meet the discharge limits for water quality and suspended solids required by the local POTW.

MAE2 used the pilot test data to design and provide written specifications for a Multi Phase Extraction and Groundwater Treatment system. The system needed to remove and treat TPH-Gasoline concentrations as high as 230,000 PPB and MTBE concentrations of 4,600 PPB along with free product gasoline.

The system uses 3 high vacuum rotary claw pumps, providing over 700 ACFM flow at 18” HG vacuum, to extract impacted groundwater and vapors. The client prefers to use multiple pumps operating in parallel rather than a single large pump. This design provides more flexibility to save energy as site needs change over time, along with redundancy to reduce downtime. The system uses a 6 point custom inlet manifold and a marine grade aluminum 120 gallon Air Water Separator.

A progressive cavity transfer pump is used to pump the water to a 20 GPM Oil Water Separator to remove any free product gasoline. Progressive Cavity pumps are selected because they do not create the chemical emulsification of the gasoline and water that other pumps cause. After the Oil Water Separator removes the free product a centrifugal transfer pump sends the water through a bag filter to remove solids and particles from the water before being treated by an oversized Poly Stackable Tray Air Stripper.

The stripper is oversized to provide additional residence time to treat the MTBE. Finally the water is pumped through another bag filter and then two 250 LB Liquid carbon vessels before being discharged to the POTW.

The custom integrated PLC control panel provides runtime hours, vacuum trends, temperature, carbon vessel pressure and water flow totals. The system uses a cellular data connection allowing full system control and data access through easy to use web browser access. The data allows easy access to system operational status and the data needed for writing reports as required by the regulators.

This Environmental Remediation System uses the following components and subsystems

Packaged Reverse Osmosis (RO) Water Treatment Systems

Commercial and Industrial RO Systems and Components

Take the expense and the mystery out of large-scale reverse osmosis plants (RO plants) with a packaged system. By making pre-designed, module-sized plants, fully assembled in standard 20-ft and 40-ft containers, the complexity and the construction of a building to house a water purification plant is no longer necessary.

Click the following link to download the RO Brochure

Active Mountaintop Gas Station Remediation Site

MAE2 was selected to design and build a remediation system for a gas station site in a small mountain town.

The geology of the area is fractured bedrock and the gasoline and MTBE contamination traveled through the fractures and impacted several nearby drinking wells. The consultant conducted a multiple day test at the site. MAE2 used this data to design a system that would prevent the contamination from moving off site and eliminate the source area. This meant the system would need to operate a large number of wells at high vacuum in order to remove the free product and create influence in the fractures to prevent the plume from traveling.

MAE2 used the pilot test data to design and provide written specifications for a Multi Phase Extraction and Groundwater Treatment system. The system needed to remove and treat TPH-Gasoline concentrations as high as 160,000 PPB and MTBE concentrations of 3,500 PPB.

The system uses 3 high vacuum rotary claw pumps, providing over 700 ACFM flow at 20” HG vacuum, to extract impacted groundwater and vapors. The pumps can be run simultaneously or independently depending upon the operational needs of the site.

The extracted groundwater from the individual wells passes through an 18 point custom manifold and settles out in a 220 gallon knock out tank. A progressive cavity transfer pump sends the water to a 20 GPM Oil Water Separator to remove any free product gasoline. A centrifugal transfer pump sends the water through a bag filter to remove solids and particles from the water before being treated by an oversized Removable Tray Air Stripper. The stripper is oversized to provide additional residence time to treat the MTBE. The water is pumped through another bag filter and then two 250 LB Liquid carbon vessels before being discharged to a mountain stream.

Finally the system will provide runtime hours, vacuum trends, and water flow totals recorded through the PLC control panel. The cellular connection allows full system control and data through easy to use web browser access. This is a vital because the town is remote and susceptible to power outages. The system can be restarted without requiring a time consuming trip, maximizing runtime.

This Gas Station Site remediation System uses the following components and subsystems

Rotary Claw Vacuum Pump

Removeable Tray Air Stripper

PLC Control panel

Bag Filter

Carbon Filtration

Oil Water Separator

Vapor Liquid Separator

Centrifugal Transfer Pump

Progressive Cavity Transfer Pump

Bio Remediation Systems

Bio Remediation Systems include Aerobic Bioremediation, Anaerobic Dechlorination and Bio Augmentation.

Aerobic Bioremediation Systems

Aerobic Bioremediation Systems are designed to deliver high volumes of dissolved oxygen and hydrocarbon degrading bacteria and nutrients to treat hydrocarbon contaminated sites. The systems provide consistent recirculation of oxygen-rich, nutrient-rich water to provide the critical requirements needed for successful in situ bioremediation. This recirculation provides the appropriate oxygen and nutrient volumes required to degrade the contaminant mass and continuous movement of the amendments throughout the site to provide maximum contact with the contaminated soils. These units can be stand alone or fully integrated into an existing or new Multi Phase Extraction System or Pump and Treat System.

Anaerobic Dechlorination Systems

Anaerobic Dechlorination Systems are designed to deliver substrates and nutrients to create the ideal site conditions for complete dechlorination of TCE, PCE, DCE and VC. The systems provide recirculation of the amended water throughout the site for maximum contact with the contaminated soils. The continuous operation allows for the correct mass delivery, and distribution to prevent biofouling and allow for complete dechlorination without stalling.

Bio Augmentation

Bio Augmentation (biologically enhanced recirculation) involves the injection and recirculation of bacteria, nutrients or substrates to create an active, balanced environment in the subsurface that biologically degrades and eliminates the contamination. MAE2 can help design fully automated and manual recirculation equipment for enhanced Bio remediation for gasoline and chlorinated solvent sites.

Positive Displacement Blowers

Process Pumping Systems

Process flow requirements and the type of fluid being pumped require careful pump selection to make sure it is compatible with your process needs. MAE2 offers a full range of pumps and materials of construction.