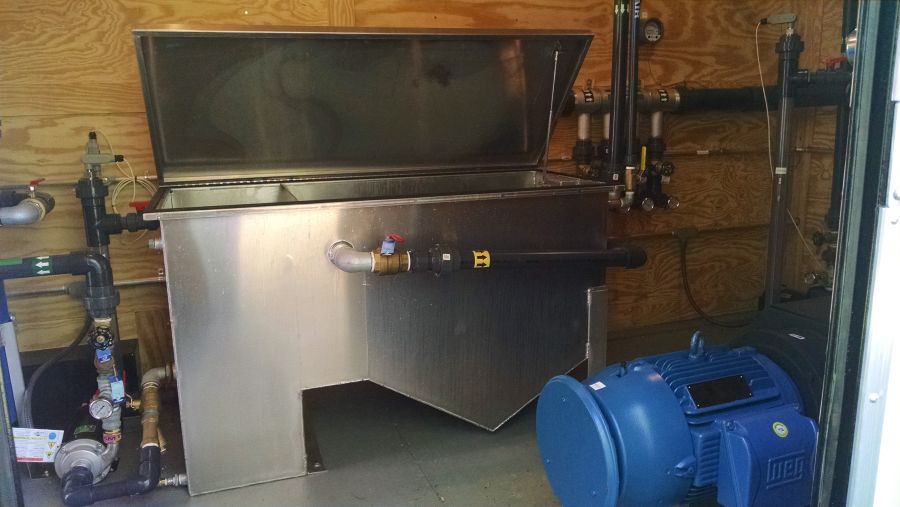

oil water separator

Heating Oil Removal System for an Apartment Building

MAE2 worked with a consultant who needed a pump and treat system to extract groundwater from two wells and then re-inject the treated water.

The project goal is to remove heating oil from the groundwater, removing any long-term liability concerns for the apartment complex owners

MAE2 built the system using a custom modified cargo container. The enclosure consisted of two rooms. The first room contained the control panel and the air supply compressor. The second room included the water treatment system and was built to meet the requirements for Class 1 Div 2 hazardous environments. Both rooms included lights, ventilation fans and heat. The system components were completely tested before shipping to make certain the system was ready to run on site with no downtime.

The system is a Pump and Treat and Groundwater Treatment system designed for up to 30 GPM water flow. MAE2 provided 2 QED AP4+ Pneumatic Groundwater Pumps complete with downwell air, water discharge and exhaust hoses and well caps. The system had a Reciprocating Air Compressor connected to an air supply manifold that included pressure and flow controls. Air hose was used to connect the trailer air supply manifold with the downwell pneumatic pumps.

The water discharge from the pumps connected to the multi point extraction manifold. The manifold piped the extracted groundwater to an Oil Water Separator to remove any free product heating oil. Any free fuel that is collected gravity drains into a 250 gallon product holding tank. A centrifugal transfer pump sends the water to two parallel high pressure fiberglass carbon vessels for treatment before discharge. The water passes through a flow totalizer to record total gallons treated prior to discharge to sanitary sewer. The system is controlled by a custom relay control panel that includes an externally mounted flashing alarm light.

Components used in this system

Relay Control panel

Reciprocating Air Compressor

Down well Pneumatic Pumps

Custom Cargo Container Enclosure

Short Term Rental System for a Groundwater Re-circulation Event at a City Gas Station

MAE2 installed a flexible pump and treat system for groundwater remediation, from our fleet of available rental systems.

MAE2 worked with a consultant who needed a pump and treat system to extract groundwater from two wells and then re-inject the treated water. The project scope called for a 1-week site event and a flexible, and readily available system was required.

Short Term Rental System for a Groundwater Recirculation Event

MAE2 provided an existing trailer mounted system from our fleet and modified it to meet the site specific needs of the short term event. MAE2 fabricated a custom reinjection manifold to make it easy to control the flow into the injection wells. The system components were completely tested before shipping to make certain the system was ready to run on site with no downtime.

The system is a Pump and Treat and Groundwater Treatment system designed for up to 30 GPM water flow. MAE2 provided 2 QED AP4+ Pneumatic Groundwater Pumps complete with downwell air, water discharge and exhaust hoses and well caps.

The system had a Reciprocating Air Compressor connected to an air supply manifold that included pressure and flow controls. Air hose was used to connect the trailer air supply manifold with the downwell pneumatic pumps. The water discharge from the pumps connected to the multi point extraction manifold. The manifold piped the extracted groundwater to an Oil Water Separator to remove any free product gasoline. Any free fuel that is collected gravity drains into a product holding tank. A centrifugal transfer pump sends the water to a Poly Stackable Tray Air Stripper. The Air Stripper removes any dissolved phase gasoline from the water. The water is then pumped through a bag filters in parallel and two high pressure steel carbon vessels for final treatment before discharge.

The pump control allows control of the pressure and flow and the custom fabricated injection manifold allows the user to fine tune the injection volume for each well. The system is controlled by a custom PLC control panel that allows for remote access and control using web-based telemetry.

This Environmental Remediation System uses the following components and subsystems

Reciprocating Air Compressor

Rental System for a Truck Stop Environmental Remediation Project

MAE2 installed a rental Dual Phase Extraction and Groundwater Treatment system to deal with a storage tank leak.

MAE2 recently started up a rental system at an active Interstate Truck Stop facility that had experienced an underground storage tank leak in the past. The consultant had performed a pilot study at the site and developed the required system performance needed to clean the site. Costs for purchasing a new custom built system were compared to buying a refurbished system and to rental of the refurbished system. The flexibility of renting an existing system that fit the site needs was determined to be the best option.

Truck Stop Environmental Remediation Project

MAE2 took an existing system from our fleet and made minor modifications. A traditional Oil Water Separator and Air stripper was replaced with an Oil Water Separator/Air Stripper Combo unit. The system components were completely tested to make the system site ready.

The system is a Dual Phase Extraction and Groundwater Treatment system designed for 10 GPM water flow and 500 ACFM vapor flow at 22” HG. There is a 5-point extraction manifold that pulls both water and vapor from the extraction wells using two 10 HP rotary claw vacuum pumps in parallel.

Rental Environmental System for a Truck Stop

The extracted groundwater is collected in the 120 G Vapor/Liquid separator and then pumped to an Oil Water Separator/Air Stripper combo unit using a progressive cavity transfer pump. Any free fuel that is extracted is collected in the OWS and gravity drains into a product holding tank. The water gravity flows into the Air Stripper chamber. The combo unit saves the need for an additional transfer pump and takes up less floor space. The water is then pumped through a bag filters in parallel and two high pressure fiberglass carbon vessels for final treatment before discharge. The OWS/Air Stripper pump is a centrifugal transfer pump. The system is controlled by a custom PLC control panel that allows for remote access and control using web-based telemetry.

This Environmental Remediation System uses the following components and subsystems

Industrial Components for Wastewater Treatment Systems

Many of the requests MAE2 receives are for single components to improve an industrial process or help remove oils or other contaminants from a waste discharge.

Are you looking to replace an existing component or add a piece of treatment equipment to meet permit conditions or simply improve the quality of the liquid or air used in a process?

Oil water separator for industrial water treatment

If you need a Vapor Liquid Separator to remove moisture from a process air flow, an Oil Water Separator to remove free oil droplets from a process discharge, or Carbon Treatment to clean air or water discharges MAE2 has the experience and knowledge to help you find the most efficient and cost effective solution.

MAE2 can help with anything from removing oils from shop floor wash water, to creating pure water using Reverse Osmosis Filtration.

MAE2 can help with anything from removing oils from shop floor wash water, to creating pure water using Reverse Osmosis Filtration.

The most common requests are for Oil Water Separators and Air Water Separators (Vapor Liquid Separators), but MAE2 can provide recommendations to successfully remove particulates, suspended solids, and dissolved contaminants.

MAE2 can provide these items as standalone units or with the additional switches, controls or components needed to integrate them fully with your existing site and equipment.