irs

Injection Platforms

The introduction of biological amendments, oxygen, chemical oxidants, nutrients, and surfactants can be very effective in reducing or degrading contaminants in soil and groundwater. The key to success for any of these approaches is contact with the contaminated soils. Continuous Injection and Recirculation can overcome the inefficiency associated with typical “slug” injection approaches. MAE2 has several injection platforms designed to achieve the contact and treatment your site requires.

Ozone Injection Systems

Anaerobic Dechlorination Systems

Aerobic Bioremediation Systems

Mobile Injection Trailer

ChemOx, Peroxide and Surfactant Injection

Chemicals are often injected into the subsurface in order to oxidize (reduce) groundwater and soil contaminants. Surfactants force soil contamination to unbind from the soils which can greatly increase the volume of contaminants removed by your pumping system. MAE2 can help you select the chemicals, surfactants, nutrients and equipment for effective site injection events.

Bio Augmentation

Bio Augmentation (biologically enhanced recirculation) involves the injection and recirculation of bacteria, nutrients or substrates to create an active, balanced environment in the subsurface that biologically degrades and eliminates the contamination. MAE2 can help design fully automated and manual recirculation equipment for enhanced Bio remediation for gasoline and chlorinated solvent sites.

SVE Enhanced Pump and Treat Systems

Soil Vapor Extraction Enhanced Pump and Treat Systems technology is the use of vacuum systems and/or sparging systems along with downwell pumps to increase the removal rate for contaminated groundwater and soil vapor. The higher vacuum increases the groundwater gradient allowing downwell pumps to remove the groundwater at a higher pumping rate. MAE2’s design team can help you select the best equipment and treatment components for your site needs.

Typical SVE systems include TEFC or XP motor, moisture separator with high level switch, inlet filter and a pre wired, pretested, custom NEMA IV control panel. Also gauges, flow indicators, temperature indicators and transmitters that can be specified per your application.

All components can be fully integrated and pre wired on a steel skid with optional custom sound attenuating enclosure or integrated with new or existing Groundwater Systems.

Options

- Skid mounted, open trailer, enclosed trailer, custom enclosure or custom building

- Centrifugal / progressive cavity automatic pump out with level controls in clear sight tube

- SVE Blower lobe auto oiler

- Filter Vessels

- Liquid Phase and Vapor Phase Carbon Vessels

- Manifolds with flow indicators and gauges

Groundwater Pump and Treat Systems

Groundwater pump and treat systems utilize downwell pumps to remove contaminated groundwater and then treat it with above ground components. MAE2 offers a full range of electric and pneumatic groundwater pumps to fit your site needs. Custom design the water treatment to include oil water separators, sediment filtration, air stripping and media treatment as needed to meet your discharge requirements.

Pneumatic Pumping Systems

Electric Submersible Pumps

Centrifugal Transfer Pump Systems

Air Strippers

Rotary Claw Compressors

Oil Water Separators

Multi-Bag/Cartridge Filter Vessels

Dual-Phase Extraction Systems

Dual Phase Extraction (also called Multi-Phase Extraction) is the use of high vacuum system to remove both contaminated groundwater and soil vapor.

MAE2 designs high vacuum systems with water and vapor treatment customized to your site needs. Combine Oil or Water Sealed Liquid Ring pumps for high vacuum and high flow, low maintenance rotary claw pumps for medium to high vacuum and high flow, or rotary lobe positive displacement pumps for low and medium vacuum and high flow with your choice of water and vapor treatment equipment.

The high vacuum dual phase extraction process involves the subsurface removal of air, water, and product. The main determining factor behind the selection of the high vacuum blower is the expected operating vacuum level. Rotary Claw blowers and Liquid ring pumps are most suitable for vacuum levels of 20-29 inches mercury (Hg). Each Dual Phase Extraction System is manufactured to meet your design and site requirements.

Landfill, Gas and Chemical Treatment Systems

Landfills have challenging requirements that require removal and control of methane, leachate and potential groundwater contaminants.

MAE2 provides a full range of landfill gas removal, leachate pumping and chemical treatment systems.

Common treatment systems for remediation of contaminants may include…

Leachate and Condensate Pumping Systems

If you need to dewater, move leachate, or pump contaminated groundwater, MAE2 has what you need. Choose from a wide range of electric and pneumatic pumps for any application.

Methane Extraction Blowers

Methane extraction is required for safety and to comply with regulations. It is important to select the correct blower to maintain an even vacuum throughout your extraction area and to match the performance of your gas flare or burner. MAE2 can provide a cost effective integrated blower package designed for your application.

Soil Vapor Extraction Systems

Soil Vapor Extraction (SVE) Systems are designed to induce vacuum and air flow to the subsurface to enhance removal of contaminants in the soil.

SVE Systems typically operate in ranged of 50” water column vacuum up to 15” Hg vacuum. A wide variety of blowers can be used based on the required vacuum and flow. Typical industry standards include regenerative blowers for low vacuum and low to moderate flow rates and positive displacement blowers for higher vacuums and higher flow rates. These types of blowers can be coupled with a variable frequency drive that allows the operator to adjust the rotational speed to match the site specific requirements.

Typical SVE systems include TEFC or XP motor, moisture separator with high level switch, inlet filter and a pre wired, pretested, custom NEMA IV control panel. Also gauges, flow indicators, temperature indicators and transmitters that can be specified per your application.

All components can be fully integrated and pre wired on a steel skid with optional custom sound attenuating enclosure or integrated with new or existing Groundwater Systems.

Options

- Skid mounted, open trailer, enclosed trailer, custom enclosure or custom building

- Centrifugal / progressive cavity automatic pump out with level controls in clear sight tube

- SVE Blower lobe auto oiler

- Filter Vessels

- Liquid Phase and Vapor Phase Carbon Vessels

- Manifolds with flow indicators and gauges

Filtration

Filtration Vessels

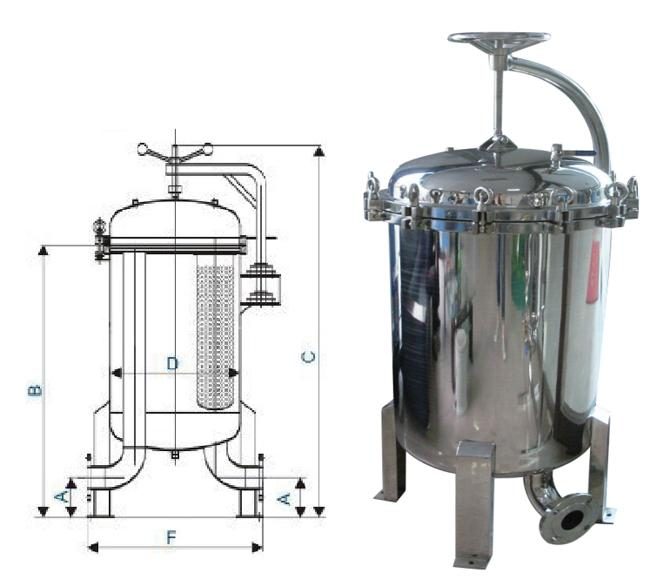

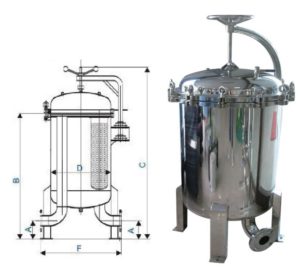

MAE2 provides a variety of standard design vessels to handle flow rates between 10-2,500 GPM and pressure rating ranging from 75-600 psi. All filter bag/strainers vessels are designed with a recessed basket and a 304 stainless steel strainer basket. Standard vessels are constructed from the highest quality carbon steel, 304 or 316 stainless steel and conform to ASME code standards.

Filter Bag/Strainer Vessels

MAE2 provides a variety of standard design vessels to handle flow rates between 10-2,500 GPM and pressure rating ranging from 75-600 psi. All filter bag/strainers vessels are designed with a recessed basket and a 304 stainless steel strainer basket. Standard vessels are constructed from the highest quality carbon steel, 304 or 316 stainless steel and conform to ASME code standards.

Multi-Bag/Cartridge Filter Vessels

Multi-bag/Cartridge vessels offer large surface areas capable of handling up to 4800 gpm in a single housing. Increasing surface area allows for longer processing time prior to filter change-out. Containing anywhere from 2 to 24 baskets in a single vessel which offers the greatest flexibility and doesn’t require a platform to be built in order to change-out or clean the filter elements or strainers.

Click for downloadable PDF of MAE2 Bag Filtration Datasheet

Sand/Media Filter

Media filters can be designed for a wide variety of solids. Typical media choices include Anthracite for course solids removal, Birm media for removal of Iron and Manganese, Filter-Lite/Sand for removal of suspended solids. These media can be installed in standard pressure vessels and designed with automatic backwashing features.

Click for downloadable PDF of MAE2 Filtration Media Datasheet

Air Sparging Systems

Air Sparging involves the injection of air or gases to the subsurface that promote enhanced degradation of contamination.

Sparge systems are designed based on required air flow and anticipated breakthrough pressure. A wide variety of blowers and compressors can be used to achieve various flow and pressure scenarios. Typical industry standards include Rotary Vane, Rotary Claw and Rotary Screw compressors.

Typical systems include discharge particulate and oil coalescing filtration to minimize oil and particulate carry over to the subsurface. In addition, a receiver tank should be installed to buffer the compressor from changes in air demand.

Typical systems include blower or compressor, TEFC or XP motor, heat exchanger if required and a prewired, pretested, custom NEMA IV control panel. Pressure gauges, flow indicators, temperature indicators and filtration can be specified per your application.

All Air Sparge Sparging components are fully integrated and prewired on a steel skid with optional custom sound attenuating enclosure. Air Sparging Systems are easily integrated with new or existing Soil Vapor Extraction Systems.

Options

- Manifolds with regulators, flow indicators and gauges

- Heat Exchanger

- Ozone Generators

- Oxygen Generators

- Remote telemetry system monitoring and alarm notification