Vessels

Filter Bag/Strainer Vessels

MAE2 provides a variety of standard design vessels to handle flow rates between 10-2,500 GPM and pressure rating ranging from 75-600 psi. All filter bag/strainers vessels are designed with a recessed basket and a 304 stainless steel strainer basket. Standard vessels are constructed from the highest quality carbon steel, 304 or 316 stainless steel and conform to ASME code standards.

Filtration

Filtration Vessels

MAE2 provides a variety of standard design vessels to handle flow rates between 10-2,500 GPM and pressure rating ranging from 75-600 psi. All filter bag/strainers vessels are designed with a recessed basket and a 304 stainless steel strainer basket. Standard vessels are constructed from the highest quality carbon steel, 304 or 316 stainless steel and conform to ASME code standards.

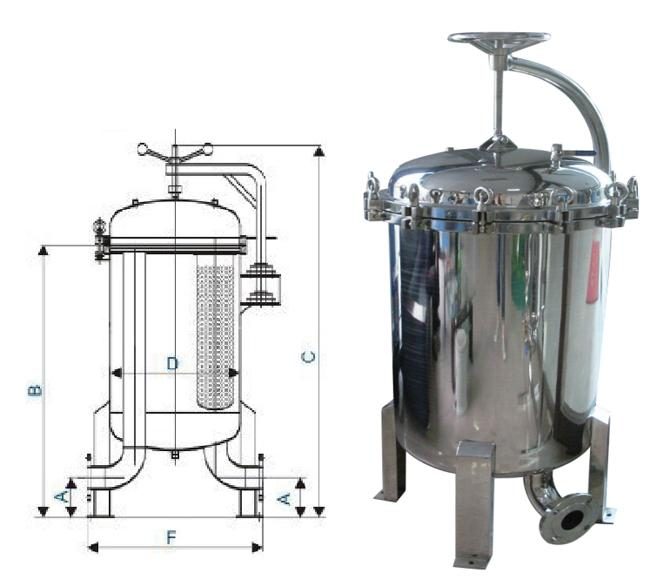

Filter Bag/Strainer Vessels

MAE2 provides a variety of standard design vessels to handle flow rates between 10-2,500 GPM and pressure rating ranging from 75-600 psi. All filter bag/strainers vessels are designed with a recessed basket and a 304 stainless steel strainer basket. Standard vessels are constructed from the highest quality carbon steel, 304 or 316 stainless steel and conform to ASME code standards.

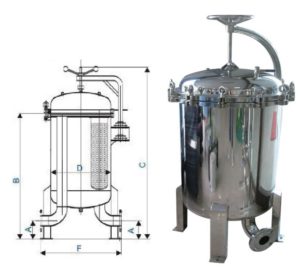

Multi-Bag/Cartridge Filter Vessels

Multi-bag/Cartridge vessels offer large surface areas capable of handling up to 4800 gpm in a single housing. Increasing surface area allows for longer processing time prior to filter change-out. Containing anywhere from 2 to 24 baskets in a single vessel which offers the greatest flexibility and doesn’t require a platform to be built in order to change-out or clean the filter elements or strainers.

Click for downloadable PDF of MAE2 Bag Filtration Datasheet

Sand/Media Filter

Media filters can be designed for a wide variety of solids. Typical media choices include Anthracite for course solids removal, Birm media for removal of Iron and Manganese, Filter-Lite/Sand for removal of suspended solids. These media can be installed in standard pressure vessels and designed with automatic backwashing features.

Click for downloadable PDF of MAE2 Filtration Media Datasheet

Carbon Filtration

Carbon filtration systems are used to remove contaminants from water and vapor.

MAE2 offer a wide range of high and low pressure liquid treatment vessels for any flow rate and vacuum and pressure vessels for vapor treatment. Virgin and regenerative granular activated carbon and a full range of specialized treatment media are also available.

Liquid and Vapor Phase Carbon Vessels

Standard Features include steel, fiberglass or marine grade aluminum constructions, access ports for carbon change out, installation of a wide variety of media engineered for your specific requirements.

Options include stainless construction, high vacuum or pressure vessels, custom hose and fittings, instrumentation, piping and valves and complete skid mounted turnkey systems.

Click for downloadable PDF on MAE2 Carbon Data Sheets

Click for downloadable Low Pressure Steel Drum Filters Data sheet

Click for downloadable High Pressure Steel Drum Filters Data sheet