Product

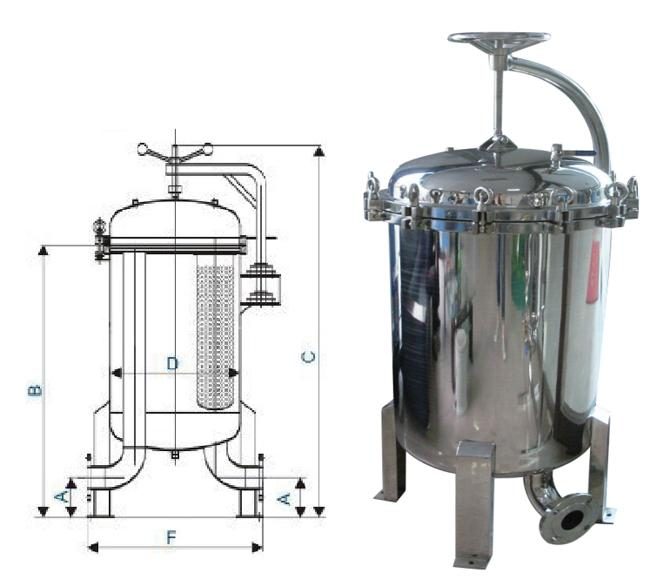

Multi-Bag/Cartridge Filter Vessels

Multi-bag/Cartridge vessels offer large surface areas capable of handling up to 4800 gpm in a single housing. Increasing surface area allows for longer processing time prior to filter change-out. Containing anywhere from 2 to 24 baskets in a single vessel which offers the greatest flexibility and doesn’t require a platform to be built in order to change-out or clean the filter elements or strainers.

Click for downloadable PDF of MAE2 Bag Filtration Datasheet

Filter Bag/Strainer Vessels

MAE2 provides a variety of standard design vessels to handle flow rates between 10-2,500 GPM and pressure rating ranging from 75-600 psi. All filter bag/strainers vessels are designed with a recessed basket and a 304 stainless steel strainer basket. Standard vessels are constructed from the highest quality carbon steel, 304 or 316 stainless steel and conform to ASME code standards.

Stackable Tray Air Strippers

The unique configuration consists of a series of integrally-molded shell/tray modules. The multiple sieve tray design uses forced-draft air bubble generation to provide rapid, effective VOC removal (up to 99%).

Every element of the heavy-duty HDPE construction has been engineered for durable, reliable performance with a multi-step positive seal against leakage.

Models are sized and priced to be the most economical choice for many low to moderate flow cleanup applications (up to 40 GPM-Poly Construction). Low capital expense and low O and M requirements make the difference.

Removable Tray Air Strippers

Removable tray air strippers are the only high-performance strippers with lightweight stainless steel body and front-slide out trays. They provide many advantages such as one-person cleaning, front serviceability and forced-draft air bubble technology. With flow rates range from 25-1000 GPM the removable tray low profile design allows them to be installed in mobile trailer, buildings and steel base skids.

Rotary Screw Compressors

Rotary Screw compressors are available with a large range of flows from 4-250 HP and air flow rates from 10 to 1500 cfm and larger. Most screw compressors have pressure ranges from 100-150 psi. Rotary screw compressors require frequent maintenance ranging from oil changes, filter changes and condensate management.

Rotary Claw Compressors

Rotary Claw compressors are available with flow rates from 65-350 cfm and pressures ranging from 15-30 psi. Claw compressors require little to no maintenance. Standard gear oil changes are 20,000 hours. Inlet filters may require more frequent changes based on the air quality of the environment in which installed.

Click to download MAE2 Rotary Claw Compressor Specifications Sheet

Rotary Vane Compressors

Rotary Vane compressors are available from very low to moderate air flows typically 3-325 cfm with pressures from 15-25 psi. Rotary Vane compressors require changing of filters and vanes on a regular basis.

Chemical Pre Treatment

Chemical Pretreatment Systems are designed to provide flocculation, coagulation, flash flocculation, pH neutralization and adjustment, metals precipitation, emulsion breaking and other reactions. Through implementation of chemical metering, agitation and pH monitoring, the CPT systems are tailored to the needs of the application.

CPTs are typically used as pretreatment prior to our DAF, SPC and oil water separator systems and can be provided as free standing, individual designs to fit your needs.

Custom tank volumes are offered to match the reaction system to the application. Reaction tanks constructed of steel, stainless steel, FRP and polyethylene are available. Customization and modifications to fit your project needs are offered.

Incline Plate Clarifiers

Incline Plate Clarifiers are designed for settling solids and precipitated metals. The compact IPCs are designed with many features and options to provide engineers and end users with convenience and flexibility in system integration choices. Customization and modifications are available.

Chemical pretreatment is typically used to improve contaminant removal. Model sizing is based on the product to be removed, flow rate and other application parameters. We offer many sizes up to 3300 square feet and many types of chemical pretreatment systems to settle solids metals and other products requiring settling. Lamella plate clarifiers are a proven technology with wide application.

Customization and modifications to fit your project needs are offered.

Dissolved Air Flotation (DAF)

Air Flotation offers process advantages over such processes as filtration, precipitation, or adsorption using natural and synthetic sorbents and media. The advantages include better treated-water quality, rapid startup, high rate operation, and a thicker sludge, shorter sludge residence time in a secondary clarifier stage and flexibility in changing the operation parameters as the result of active sludge separation.

DAF bubbles are formed by a reduction of pressure of a super air saturated water stream at pressures usually higher than 3 atm. In industrial practice, the supersaturated water is forced through precise needle valves for air control, and clouds of 0.02–0.10 mm bubbles in diameter are subsequently produced and mixed with the incoming waste stream. Once the saturated stream pressure is reduced and the two streams mixed the bubbles attach to the materials being separated and then floats to the water surface. Modern flotation devices and schemes exhibit both high throughput and efficiency.

Products removed: solids, oils, fuels (vehicle/jet), fuel oils, hydraulic fluids, immiscible machining oils, lube oil, transmission fluid, vegetable based oils, animal/vegetable by-products and many other products.