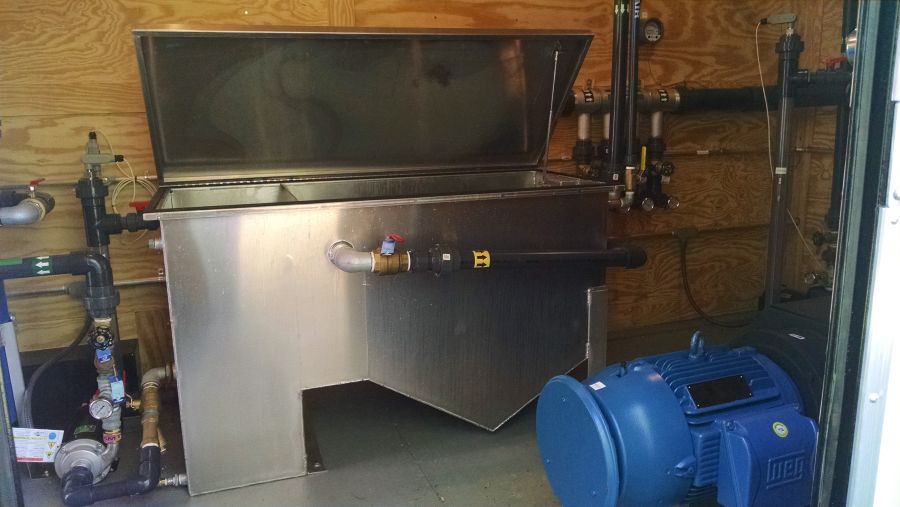

vapor liquid separator

Rail Yard Iron and Suspended Solids Treatment System Upgrade and Expansion

MAE2 was selected to provide a system to remove iron and suspended solids and to fully integrate into the operation of an existing system and controls.

While many companies have the ability to build a new system based upon a written specification, expanding an existing system and seamlessly integrating the new components and controls requires extensive industry knowledge and experience. MAE2 was selected to provide a system to remove iron suspended solids and to fully integrate into the operation of the existing system and controls.

The fouling and constant maintenance caused by the iron and suspended solids was preventing the existing water treatment system from effectively reaching the treatment goals required. MAE2’s 23 years of groundwater system design experience, our flexible manufacturing capacity and our UL control panel shop made us the perfect partner to help create a successful solution for a challenging site.

MAE2 worked with the consulting engineer to understand the existing system operation and plan the best way to augment the system and improve the treatment results. The existing system included electric and pneumatic submersible pumps that pumped fuel contaminated groundwater to an air stripper for treatment.

MAE2 worked to design and fabricate custom tanks and to design and program a custom PLC control panel to work with the existing treatment system. In the new expanded system, the extracted groundwater is pumped into a new, custom fabricated, 3000-gallon aeration tank. A chemical metering pump is used to add chemicals into the aeration tank to help precipitate dissolved iron.

Two 5 HP Rotary Claw Compressors skid mounted in parallel provide aeration in the tank at 82 CFM and 22 PSI. Fuel vapors created in the aeration tank are removed by a 3 HP regenerative vacuum blower operating at 55 CFM and 58” WC vacuum. Any residual moisture is captured in an 80-gallon Vapor Liquid Separator that includes a High-Level alarm switch and manual drain.

The vapor steam passes through the blower and then a ½ HP heat exchanger to reduce the temperature so that the 200 LB steel vapor carbon vessel can effectively remove any fuel vapors before discharging to the atmosphere. The Aeration tank is equipped with a user programmable level transmitter that controls the on/off operation of a 200 GPM, 5 HP Centrifugal Transfer Pump. The water is pumped to a custom, three stage clarifier tank.

The tank includes a polymer metering system followed by a flash chamber and electronic mixer, a flocculent chamber and electronic mixer and finally an inclined plate clarifier with hopper bottom. This removes most of the larger suspended solids and precipitated iron. The water gravity feed into a custom, 1000 gallon filtration feed tank. In order to remove any fine suspended solids, the water is pumped through a fully automated, four vessel, sand filter system.

The sand filter includes a 3000 gallon, backwash water tank and a 3000 gallon, backwash solids tank. The system PLC control panel uses pressure transmitters and automated ball valves to backwash the sand filters and pumps the captured solids to the holding tank without stopping treatment flow. A 63 GPM sludge pump controlled by a user programmable level transmitter pumps the collected solids to a custom, 3000 Gallon Settling Tank. The tank has a sludge/solids settling basin in the bottom and a custom designed liquid decanting valve system to drain liquids. The treated, solids-free water, effluent from the sand filtration system is pumped to the existing air stripper for final treatment and removal of any remaining fuel.

This Remediation System uses the following components and subsystems

Regenerative Vacuum Pump

Sand Filter

Rotary Claw Compressor

Incline Plate Clarifiers

Chemical Pre Treatment Systems

Vapor Phase Carbon

Rental System for Remediation of a Redevelopment site.

MAE2 was selected to provide a rental system to remediate a former gas station site that had been redeveloped.

MAE2 had previously provided a rental system that successfully removed most of the gasoline contamination from the site but had to be removed to allow for construction when the property was sold for redevelopment. The remaining fuel contamination was concentrated in a smaller area. Renting a system was a perfect option for this site. After the site was redeveloped, a different smaller system was chosen to complete the site remediation saving both rental and operating cost.

The fuel contamination was limited to the vadose zone soils, so the system selected was an air sparge, soil vapor extraction system. This involves pumping air into the pressure wells to volatilize residual fuel and to stimulate bio remediation activity. The soil vapor extraction creates further volatilization and extraction of soil vapors. The system is enclosed in an 8’ x 14’ utility trailer with insulated walls and ventilation fan and lights.

The air sparge unit is a 7.5 HP Rotary Vane Compressor capable of providing 55 ACFM @ 20 PSI to a two point manifold with each leg including a pressure gauge and a ball valve. The vapor wells are connected to a two point extraction manifold that includes a gate valve and vacuum gauge for each leg. The soil vapor extraction consists of a marine grade aluminum vapor liquid separator and a 15 HP regenerative vacuum blower capable of 350 SCFM @ 85” WC vacuum. The vapor liquid separator includes a centrifugal transfer pump to empty any water that is collected. The system includes a relay based control panel to allow for simple fully automated control.

This Remediation System uses the following components and subsystems

Regenerative Vacuum Pump

Rotary Vane Air Compressor

Rotary Claw Compressor

Industrial Components for Wastewater Treatment Systems

Many of the requests MAE2 receives are for single components to improve an industrial process or help remove oils or other contaminants from a waste discharge.

Are you looking to replace an existing component or add a piece of treatment equipment to meet permit conditions or simply improve the quality of the liquid or air used in a process?

Oil water separator for industrial water treatment

If you need a Vapor Liquid Separator to remove moisture from a process air flow, an Oil Water Separator to remove free oil droplets from a process discharge, or Carbon Treatment to clean air or water discharges MAE2 has the experience and knowledge to help you find the most efficient and cost effective solution.

MAE2 can help with anything from removing oils from shop floor wash water, to creating pure water using Reverse Osmosis Filtration.

MAE2 can help with anything from removing oils from shop floor wash water, to creating pure water using Reverse Osmosis Filtration.

The most common requests are for Oil Water Separators and Air Water Separators (Vapor Liquid Separators), but MAE2 can provide recommendations to successfully remove particulates, suspended solids, and dissolved contaminants.

MAE2 can provide these items as standalone units or with the additional switches, controls or components needed to integrate them fully with your existing site and equipment.