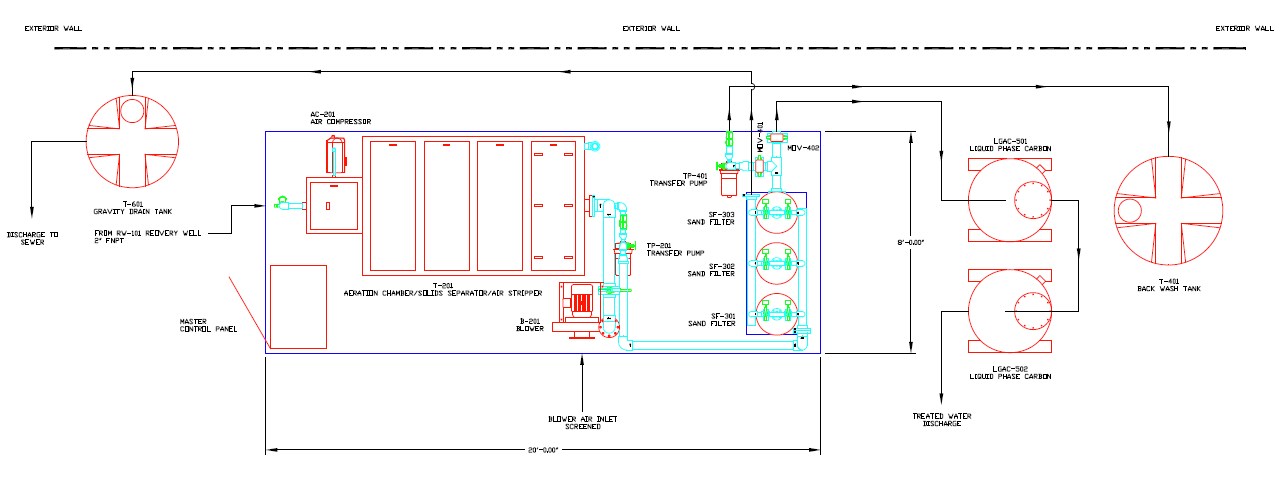

Marine Research Groundwater Treatment System

Variable Flow Industrial Process Treatment System

MAE2 was tasked with designing a system to treat process water to remove iron and fuel contamination for a marine research center. The research center used local groundwater to supply fresh water to fish tanks used for scientific research. The groundwater had been impacted with fuel from a nearby gas station and was high in iron bacteria. The fuel needed to be removed from the water to keep the fish healthy and the iron needed to be removed to keep it from fouling the drum filters that provided the filtered water required in the tanks. The system needed to handle flows that ranged from 8 GPM to peak flows of 45 GPM. The facility wanted to reduce electrical power costs by only operating at full power during peak times and adjusting the power down during lower flow periods.

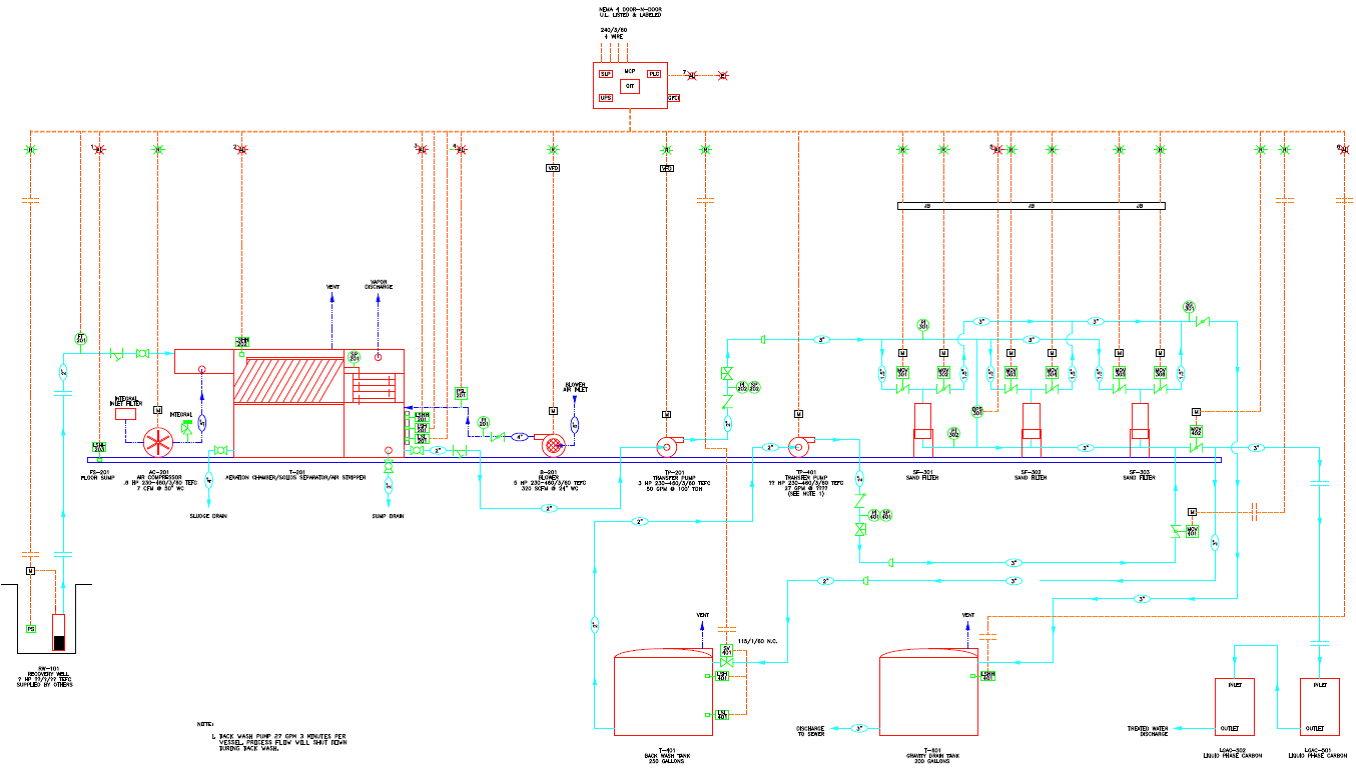

MAE2 designed a system with a fully automated PLC control panel. The PLC constantly measures the incoming flow rate and uses Variable Frequency Drives (VFDs) to adjust the motor speeds to match the flow rate. The PLC controls also monitor system pressures and automatically initiates a system backwash to clear the iron filters and reduce manual cleaning labor. The system is designed to keep a continuous water supply to the research tanks even during the back wash cycles.

This turnkey MAE2 solution reduces on site maintenance, electrical power usage, and provides treated process water in a compact fully automated package that adjusts to the constantly changing site conditions. This system is expected to go online this upcoming summer.

Click on diagram to see another.

The groundwater treatment system consisted of an aeration chamber and slant plate clarifier to precipitate and collect iron, a removable tray air stripper to remove the dissolved gasoline, a back-washing filtration media system to remove any fine particulate and finally liquid carbon media vessels as a final safety to remove any potential remaining gasoline.