Project Summary

Rental System for a Truck Stop Environmental Remediation Project

MAE2 installed a rental Dual Phase Extraction and Groundwater Treatment system to deal with a storage tank leak.

MAE2 recently started up a rental system at an active Interstate Truck Stop facility that had experienced an underground storage tank leak in the past. The consultant had performed a pilot study at the site and developed the required system performance needed to clean the site. Costs for purchasing a new custom built system were compared to buying a refurbished system and to rental of the refurbished system. The flexibility of renting an existing system that fit the site needs was determined to be the best option.

Truck Stop Environmental Remediation Project

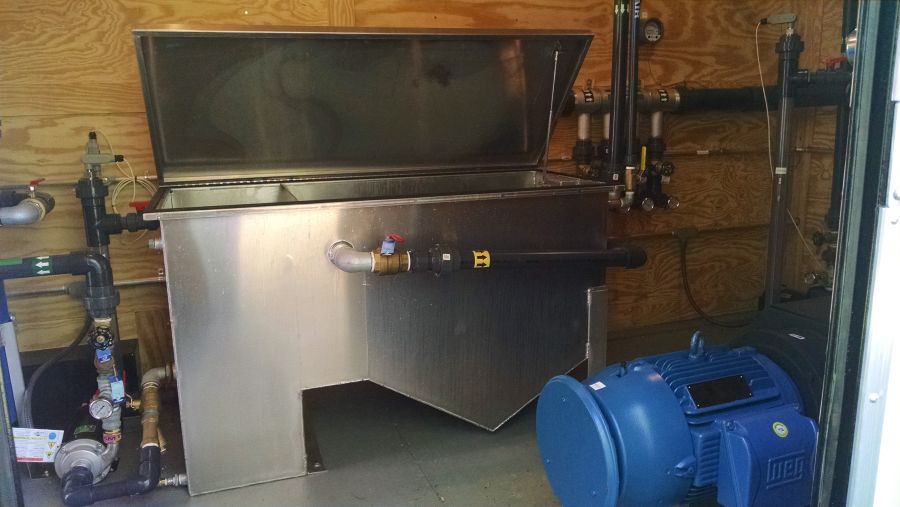

MAE2 took an existing system from our fleet and made minor modifications. A traditional Oil Water Separator and Air stripper was replaced with an Oil Water Separator/Air Stripper Combo unit. The system components were completely tested to make the system site ready.

The system is a Dual Phase Extraction and Groundwater Treatment system designed for 10 GPM water flow and 500 ACFM vapor flow at 22” HG. There is a 5-point extraction manifold that pulls both water and vapor from the extraction wells using two 10 HP rotary claw vacuum pumps in parallel.

Rental Environmental System for a Truck Stop

The extracted groundwater is collected in the 120 G Vapor/Liquid separator and then pumped to an Oil Water Separator/Air Stripper combo unit using a progressive cavity transfer pump. Any free fuel that is extracted is collected in the OWS and gravity drains into a product holding tank. The water gravity flows into the Air Stripper chamber. The combo unit saves the need for an additional transfer pump and takes up less floor space. The water is then pumped through a bag filters in parallel and two high pressure fiberglass carbon vessels for final treatment before discharge. The OWS/Air Stripper pump is a centrifugal transfer pump. The system is controlled by a custom PLC control panel that allows for remote access and control using web-based telemetry.

This Environmental Remediation System uses the following components and subsystems

Multi Phase Extraction at a Bulk Fuel Terminal

MAE2 was asked to provide a bid for an environmental remediation project to clean up the groundwater and soil at a Bulk Fuel terminal for a Major Oil Bulk Fuel facility.

MAE2 was selected after a thorough review determined that the equipment and pricing proposal, for a Multi Phase Extraction system represented the most responsive and cost effective solution for the site.

The site clean-up goals required draw-down of the site groundwater followed with high vacuum Soil Vapor Extraction to clean the soils in the vadose zone and dewatered saturated soils. The water is to be treated to meet standards for surface water discharge. The contaminated vapors are to be treated using an electric oxidizer.

The Multi Phase Extraction system design is for the equipment to be contained in two enclosed cargo trailers. The use of two trailers allows for flexibility to locate and move the system around the site as needed.

Trailer 1 Multi-Phase extraction system

Trailer 1 is a two room trailer that contains the main system control panel and a rotary screw compressor in an air conditioned non hazardous room. The air compressor provides the air supply required to operate eight downwell pneumatic pumps. Room 2 includes the air supply manifold for the pneumatic pumps and the extraction manifold SVE wells. Two 15 HP rotary claw vacuum pumps provide up to 730 ACFM at 25” HG. Any moisture and groundwater extracted is collected in the Vapor liquid separator and is then pumped over to the groundwater treatment system housed inside trailer 2 using a progressive cavity transfer pump. The extracted vapors are treated with a 600 SCFM electric oxidizer located within room 2. The oxidizer uses an automated vapor control valve to automatically adjust the vacuum to keep the vapor concentrations within the treatment range for complete destruction. Room 2 is designed to meet Class 1 Div 2 standards for hazardous locations and also includes a high LEL alarm that shuts the system down if explosive vapors are present.

Trailer 2 Multi-Phase extraction system

Trailer 2 contains the groundwater treatment system designed treat water at flows up to 60 GPM. The trailer 2 interior is built to Class 1 Div 2 standards for hazardous locations. There is a groundwater influent manifold that allows individual well control and has a flow transmitter for each leg that records gpm flow and total gallons on the PLC control panel display. An explosion proof chemical metering pump injects into the manifold header discharge to treat the water to prevent iron scaling. The groundwater flows into a cone bottom separator tank to collect any solids and allow any free gasoline to separate to the top. Water then flows into a large EQ tank and is pumped through bag filters to remove sediment to a removable tray air stripper using a centrifugal transfer pump. From the air stripper the water is pumped through two 750 LB steel carbon vessels and then to discharge. The trailer is designed with waterproof floor and a waterproof containment equal to 110% of the holding tank volume. The trailer has a floor sump alarm to shut the system down in case of a water leak and similar to trailer 1 has a high LEL alarm.

Components of the Multi-Phase extraction system

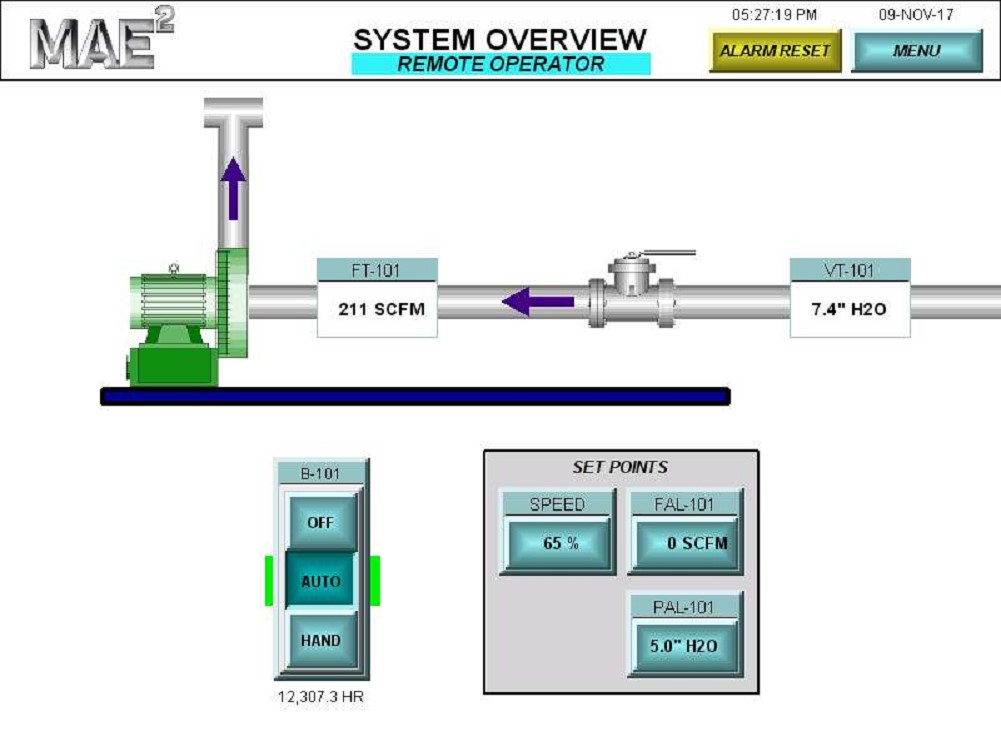

Each trailer has its own PLC control panel with a color touch screen display. The control panels are connected via an Ethernet communication cable. An operator can access either control panel from each individual panel screen or from a remote internet connection. The control panel allows each system to operate independently or to be interlocked together and records all alarms, flows, pressures and vacuum. Alarms notifications are sent via email or text and the system can be accessed remotely through a web based connection.

This Environmental Remediation System uses the following components and subsystems

Progressive Cavity Transfer Pump

Chemical metering pump

Long Term Rental System Fits Need for a Site Remediation Project at a Golf Course Maintenance Facility

Rental Systems provide options. Do you have a site that may clean up within a year? Is it easier to make monthly payments rather than a large one time capital expenditure? Do you have multiple sites that could share a mobile remediation system? Is the funding source only approved for one year or less?

These are all great reasons for choosing to rent a system. Many of our customers have projects where they anticipate a quick clean up timeframe. Others are working with a project manager that may only want to commit to one year of project funding at a time. And sometimes it is just easier to pay a monthly fee than it is to pay for an entire system and wait for reimbursement. Renting a system offers flexibility to adapt to site or funding changes. Also, since rental systems are already assembled, the time from purchase order to start up is much quicker.

MAE2 will help you select a system from our fleet that closely matches your site needs. MAE2 will also work with you to make small custom changes to make the system fit your site. All of our rental systems are cleaned, adapted and thoroughly tested prior to shipping to your site. Here are some examples of remediation systems available to rent

MAE2 took an existing system from our fleet and made minor modifications. The manifold was increased to add additional extraction points to match the total number of on-site extraction wells. The system components were completely tested and a full O & M and cleaning was conducted to make the system site ready.

On Site Deployment

The system is a Dual Phase Extraction and Groundwater Treatment system designed for 10 GPM water flow and 365 ACFM vapor flow at 25” HG. There is a 12 point extraction manifold that pulls both water and vapor from the extraction wells using a 15 HP rotary claw vacuum pump. The extracted groundwater is collected in the 120 G Vapor/Liquid separator and then pumped to an Oil Water Separator (OWS) using a progressive cavity transfer pump. Any free fuel that is extracted is collected in the OWS and gravity drains into a product holding tank.

The water is pumped from the OWS to a Poly Stackable Tray Air Stripper and the pumped through a bag filter and two high pressure fiberglass carbon vessels for final treatment before discharge. The OWS pump and Air Stripper pump are centrifugal transfer pumps. The system is controlled by a custom PLC control panel that allows for remote access and control using web based telemetry.

This Environmental Remediation System uses the following components and subsystems

Active Dairy Farm Environmental Remediation System

MAE2 was selected to design and build a remediation system for this Active Dairy Farm that incorporates an on-site trucking company to get the product to market.

The consultant selected MAE2 to build for a vacuum enhanced groundwater pump and treat and air sparge remediation system that incorporated down well groundwater pumps and high vacuum DPE (Dual Phase Extraction) in order to remove the free product and lower the dissolved phase gasoline concentrations. The system also includes Air Sparging in order to volatilize VOC’s in the vadose zone and stimulate bio activity.

MAE2 recommended high vacuum parallel rotary claw pumps along with 5 QED pneumatic auto pumps to dewater the wells and expose more soil the influence of the SVE and the rotary claw compressor used for air sparging. The rotary claw vacuum pumps were chosen to allow the system flexibility to operate at a wide range of vacuum levels. The flexibility allows the system to operate at low vacuum to help slurp the free product in the wells while pumping at a low rate to maximize the initial free product recovery.

The pneumatic auto pumps operate on demand with a 10 HP reciprocating air compressor providing the air supply needed for pumping. The Groundwater Treatment system consists of an air water separator, an oil water separator the remove free product and a removable tray air stripper to remove the dissolved phase gasoline before discharging to surface water. At system start up the groundwater pumps were set just below the water table in order to slowly recover the free product and the vacuum was set at 12” HG to enhance product recovery.

Once the free product is reduced in the recovery wells, the well pumps will be set deeper and pump at a higher volume and the vacuum level will be increased. The rotary claw sparge compressor will also be started to maximize the treatment and reduce the project run time. An enclosed steel frame utility trailer was chosen for the project to maximize flexibility and mobility.

The regulatory agency requires consistent run time for all approved systems. The system provides run time hours, vacuum trends, and water flow totals recorded through the PLC control panel. The cellular connection allows full system control and data through easy-to-use web browser access. The instant alarm notification and remote control allows the consultant to immediately respond to any changing site conditions and maximize system run time.

This Environmental Remediation System uses the following components and subsystems

Rotary Claw Vacuum Pump

Removable Tray Air Stripper

PLC Control panel

Oil Water Separator

Vapor Liquid Separator

Centrifugal Transfer Pump

Progressive Cavity Transfer Pump

Reciprocating Air Compressor

Down well Pneumatic Pumps

Rotary Claw Compressor

Please contact MAE2 for assistance for all your environmental needs.

Vapor Intrusion Mitigation System for Active Manufacturing Facility

MAE2 was selected to build a Sub Slab Depressurization system for an active manufacturing facility.

The factory has been in continuous use since the 1950s. In the past, releases of chlorinated solvents, used in the manufacturing process, had contaminated the soil and groundwater beneath the building. Testing confirmed that Volatile Organic Compounds (VOC’s) were migrating into the building. There is no space for the Vapor Mitigation System on the factory floor since this is an active manufacturing facility and all the floor space is needed for the process equipment and the free flow of equipment and workers.

MAE2 worked with the consultant to design a lightweight unit that could be mounted on the roof and when operating create a vacuum in the sub slab that would prevent the VOC’s from migrating into the manufacturing spaces.

The skids were designed with trouble free, simple weather proof controls to maximize system up time. The skids were built with marine grade aluminum, selected because it is both lightweight and corrosion resistant. The blower design was for the blower to operate at up to 600 SCFM at 16” WC vacuum. The design also included a Variable Frequency Drive (VFD) so that the blower could be adjusted to match site demand and flexibility. A simple touch of a button and the flow can be adjusted up or down to meet any changing conditions.

The run time and ability to adjust and monitor the system is critical because the factory is constantly occupied with employees. Because the site is several hours from the consultant, it was designed with a simple remote access telemetry system. The consultant receives daily run status reports and alarm notifications via email, allowing them to monitor and adjust the system operation. The system can also be started, stopped and have the flow adjusted simply by logging in from any computer or smart phone.

The system runs continuously and has already run for well over 10,000 hours. The consultant on the project made the following comment.

“The system has been very reliable and has operated on a 24/7 schedule with very little downtime. The remote access makes it easy to check on the system performance without actually having to travel to the site. We are pleased with the system fabrication, production, and support that Mid-Atlantic Environmental Equipment, Inc. has provided for this project.”

Rich Cherico, Project Manager, Amec Foster Wheeler

This Environmental Remediation System uses the following components and subsystems

Pressure Blower

Marine Grade Aluminum Skid

PLC Control Panel

Please contact MAE2 for assistance for all your environmental needs.

Industrial Components for Wastewater Treatment Systems

Many of the requests MAE2 receives are for single components to improve an industrial process or help remove oils or other contaminants from a waste discharge.

Are you looking to replace an existing component or add a piece of treatment equipment to meet permit conditions or simply improve the quality of the liquid or air used in a process?

Oil water separator for industrial water treatment

If you need a Vapor Liquid Separator to remove moisture from a process air flow, an Oil Water Separator to remove free oil droplets from a process discharge, or Carbon Treatment to clean air or water discharges MAE2 has the experience and knowledge to help you find the most efficient and cost effective solution.

MAE2 can help with anything from removing oils from shop floor wash water, to creating pure water using Reverse Osmosis Filtration.

MAE2 can help with anything from removing oils from shop floor wash water, to creating pure water using Reverse Osmosis Filtration.

The most common requests are for Oil Water Separators and Air Water Separators (Vapor Liquid Separators), but MAE2 can provide recommendations to successfully remove particulates, suspended solids, and dissolved contaminants.

MAE2 can provide these items as standalone units or with the additional switches, controls or components needed to integrate them fully with your existing site and equipment.

Industrial Components for Wastewater Treatment Systems often use the following components and subsystems

City Convenience Store Environmental Remediation Site

MAE2 was selected to design and build a remediation system for a convenience store site in mixed use city location.

The consultant conducted a multiple day test at the site. The pilot study indicated a need for a high vacuum system that could treat extracted groundwater at 10-15 GPM and to remove large amounts of free product gasoline. MAE2 used this data to design a system that would extract and treat groundwater and free product from 6 wells located on site. The water needed to be treated to meet the discharge limits for water quality and suspended solids required by the local POTW.

MAE2 used the pilot test data to design and provide written specifications for a Multi Phase Extraction and Groundwater Treatment system. The system needed to remove and treat TPH-Gasoline concentrations as high as 230,000 PPB and MTBE concentrations of 4,600 PPB along with free product gasoline.

The system uses 3 high vacuum rotary claw pumps, providing over 700 ACFM flow at 18” HG vacuum, to extract impacted groundwater and vapors. The client prefers to use multiple pumps operating in parallel rather than a single large pump. This design provides more flexibility to save energy as site needs change over time, along with redundancy to reduce downtime. The system uses a 6 point custom inlet manifold and a marine grade aluminum 120 gallon Air Water Separator.

A progressive cavity transfer pump is used to pump the water to a 20 GPM Oil Water Separator to remove any free product gasoline. Progressive Cavity pumps are selected because they do not create the chemical emulsification of the gasoline and water that other pumps cause. After the Oil Water Separator removes the free product a centrifugal transfer pump sends the water through a bag filter to remove solids and particles from the water before being treated by an oversized Poly Stackable Tray Air Stripper.

The stripper is oversized to provide additional residence time to treat the MTBE. Finally the water is pumped through another bag filter and then two 250 LB Liquid carbon vessels before being discharged to the POTW.

The custom integrated PLC control panel provides runtime hours, vacuum trends, temperature, carbon vessel pressure and water flow totals. The system uses a cellular data connection allowing full system control and data access through easy to use web browser access. The data allows easy access to system operational status and the data needed for writing reports as required by the regulators.

This Environmental Remediation System uses the following components and subsystems

Vapor Intrusion Mitigation System for Brownfield Redevelopment

MAE2 was selected to help design an active Sub Slab Depressurization system for a new construction site that had high levels of TCE and PCE in the soils.

The project goal was to redevelop a former factory building creating new retail, restaurant, and office space. A solution needed to be developed to keep any contaminated vapors in the soils from releasing into the occupied building spaces. Space was a premium, so the system needed to protect the building occupants with as small a footprint as possible.

MAE2 worked with the consultant prior to the building construction to design an active vacuum blower system that had enough capacity to remove any vapors from the sub slab. Three outdoor weather skids that would be placed upon the building roof were selected so that no valuable floor space would be lost.

The skids were designed with trouble free, simple weather proof controls to maximize system up time. A series of slotted pipes were placed underneath the building slab and connected to a main trunk line that extended to the roof and connected to the blowers. The design goal was to prevent any hazardous vapors that reached the sub slab foundation from intruding into the occupied areas above. There were two smaller areas in one building section and a larger area in a second section. The smaller zones were connected to 10 HP pressure blowers and the larger zone was connected to a 20 HP blower. The blowers were designed for vacuum applications and are able to move large volumes of air at 20” WC.

The start up of the sub slab depressurization skids was very successful and the high volume air exchange had significant influence and prevented measurable volumes of TCE, PCE vapors from entering the finished spaces.

Active Mountaintop Gas Station Remediation Site

MAE2 was selected to design and build a remediation system for a gas station site in a small mountain town.

The geology of the area is fractured bedrock and the gasoline and MTBE contamination traveled through the fractures and impacted several nearby drinking wells. The consultant conducted a multiple day test at the site. MAE2 used this data to design a system that would prevent the contamination from moving off site and eliminate the source area. This meant the system would need to operate a large number of wells at high vacuum in order to remove the free product and create influence in the fractures to prevent the plume from traveling.

MAE2 used the pilot test data to design and provide written specifications for a Multi Phase Extraction and Groundwater Treatment system. The system needed to remove and treat TPH-Gasoline concentrations as high as 160,000 PPB and MTBE concentrations of 3,500 PPB.

The system uses 3 high vacuum rotary claw pumps, providing over 700 ACFM flow at 20” HG vacuum, to extract impacted groundwater and vapors. The pumps can be run simultaneously or independently depending upon the operational needs of the site.

The extracted groundwater from the individual wells passes through an 18 point custom manifold and settles out in a 220 gallon knock out tank. A progressive cavity transfer pump sends the water to a 20 GPM Oil Water Separator to remove any free product gasoline. A centrifugal transfer pump sends the water through a bag filter to remove solids and particles from the water before being treated by an oversized Removable Tray Air Stripper. The stripper is oversized to provide additional residence time to treat the MTBE. The water is pumped through another bag filter and then two 250 LB Liquid carbon vessels before being discharged to a mountain stream.

Finally the system will provide runtime hours, vacuum trends, and water flow totals recorded through the PLC control panel. The cellular connection allows full system control and data through easy to use web browser access. This is a vital because the town is remote and susceptible to power outages. The system can be restarted without requiring a time consuming trip, maximizing runtime.

This Gas Station Site remediation System uses the following components and subsystems

Rotary Claw Vacuum Pump

Removeable Tray Air Stripper

PLC Control panel

Bag Filter

Carbon Filtration

Oil Water Separator

Vapor Liquid Separator

Centrifugal Transfer Pump

Progressive Cavity Transfer Pump

Former Gas Station Remediation site

MAE2 was selected to design and build a remediation system for a closed gas station site in a mixed residential/commercial area after providing the most responsive and cost effective bid.

The consultant put out a request for proposals (RFP) for a dual phase remediation system with groundwater treatment that requested a combination of down well groundwater pumps high vacuum SVE (Soil Vapor Extraction) using 12 wells in order to remove the free product and lower the dissolved phase gasoline concentrations to reach site closure standards.

MAE2 responded to the RFP by proposing a high vacuum oil sealed LRP (liquid ring pump) along with 12 QED pneumatic auto pumps to dewater the wells and expose more soil the influence of the SVE. The LRP was chosen because the immediate proximity of residential neighbors required a pump that operated more quietly than other high vacuum options. The pneumatic auto pumps operate on demand with a 15 HP reciprocating air compressor providing the air supply needed for pumping.

The Groundwater Treatment system consisted of an oil water separator the remove free product and a removable tray air stripper to remove the dissolved phase gasoline before discharging to surface water. At system start up the groundwater pumps maintained a groundwater pumping rate of 30 GPM and the LRP maintained a vacuum influence of 20” HG across the site. A steel frame building with sound hoods and sound insulation inside the walls was chosen because of the numerous nearby residences.

The regulatory agency requires consistent run time for all approved systems. The system provides run time hours, vacuum trends, and water flow totals recorded through the PLC control panel. The cellular connection allows full system control and data through easy-to-use web browser access. The instant alarm notification and remote control allows the consultant to immediately respond to any changing site conditions and maximize system run time.

This Gas Station Site remediation System uses the following components and subsystems

Oil Sealed Liquid Ring Vacuum Pump

Removable Tray Air Stripper

PLC Control panel

Oil Water Separator

Vapor Liquid Separator

Centrifugal Transfer Pump

Progressive Cavity Transfer Pump

Reciprocating Air Compressor

Down well Pneumatic Pumps