Landfill, Gas, Chemicals

Municipal Landfill Project to Remediate PCE, TCE, Vinyl Chloride and Methane

MAE2 has a full range of systems for recovery of landfill methane and VOC contamination.

Landfill systems operate in some of the harshest conditions and must be designed with those conditions in mind. MAE2 has the experience and capability to build a landfill gas system for your specific application. Blower sizing, material compatibility, and NEC electrical classification design are all critical to the success of your project.

MAE2 was contacted by a municipal landfill to replace the main components of an existing blower system that operates within a landfill cell that is contaminated with PCE, TCE and Vinyl Chloride along with methane. The blower extracts the contaminated VOC’s and methane and then a propane enhanced flare destroys the contamination. The blower had failed and the vapor liquid separator had corroded from exposure to the elements and the solvents.

MAE2 recommended our Marine Grade Aluminum Vapor Liquid Separator to offer better protection from the corrosive VOC’s and the exposure to the weather.

MAE2 selected a regenerative blower based upon the system performance needs and the existing site conditions. The landfill was able to benefit from a lower cost blower selected to meet their current needs rather than replacing the existing blower with the same model. MAE2 assisted with the connection and integration of the new equipment into the existing system and provided complete start up and testing. MAE2 was able to use our experience to help this municipal landfill operation select and implement a cost-effective solution that will keep them operating trouble free for years to come.

This Landfill remediation project uses the following components and subsystems

Regenerative Vacuum Blower

Marine Grade Aluminum 60 Gallon Vapor Liquid Separator

Landfill Leachate and Contaminated Groundwater Removal

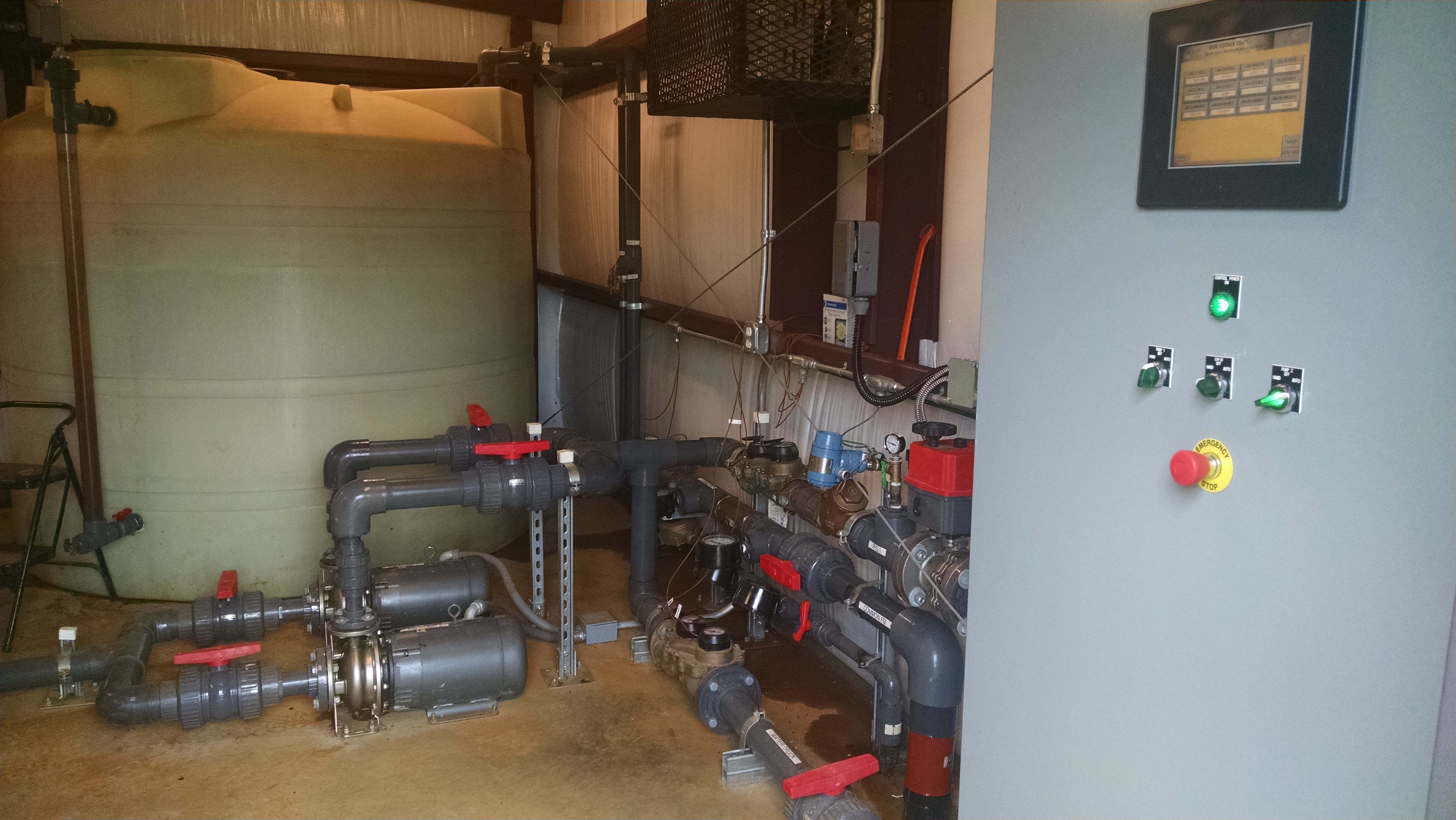

200 GPM Leachate and Contaminated Groundwater Removal

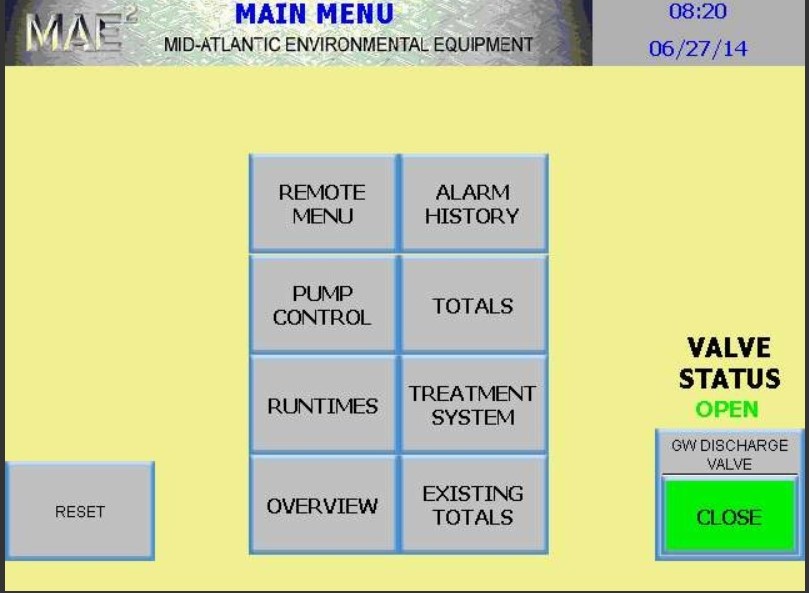

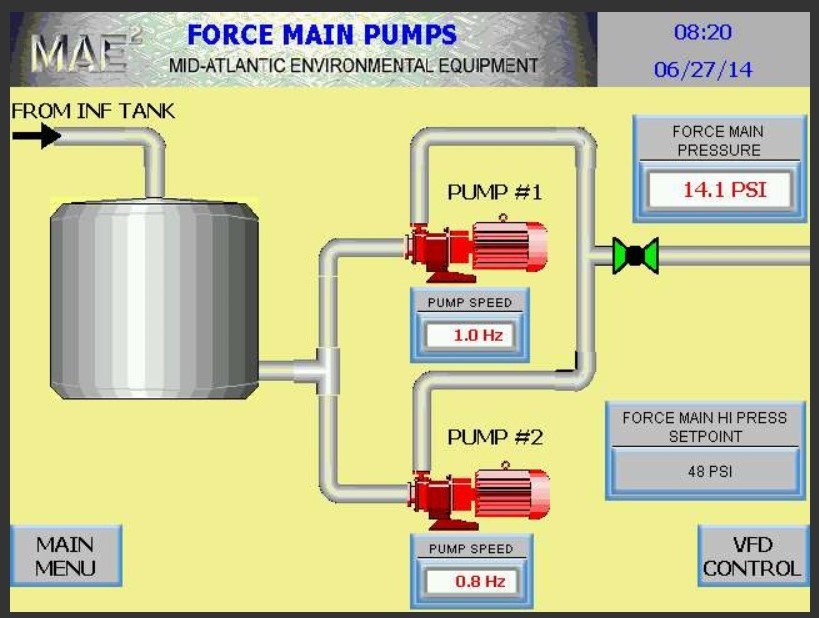

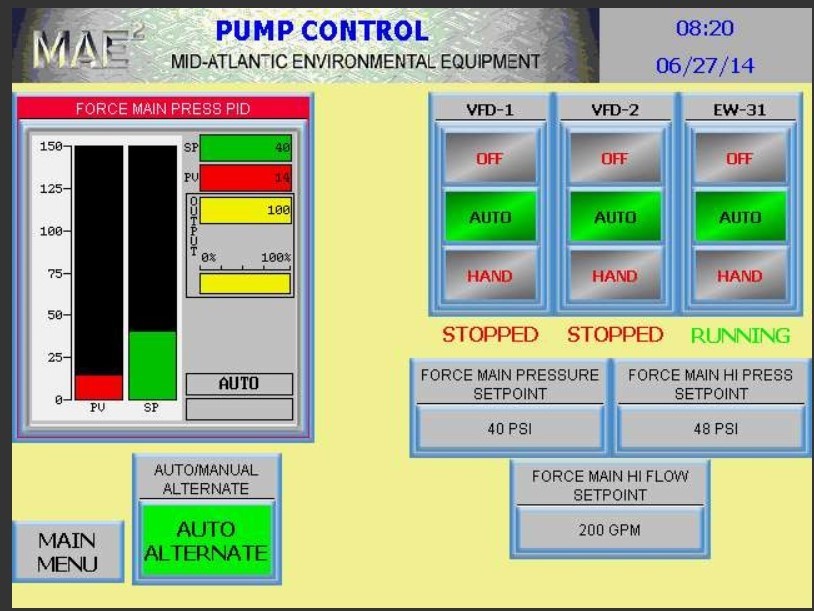

This required a main control panel that provided remote access and control over the groundwater and leachate building while still allowing for local control from each building. The 17 groundwater pumps in the existing building and the 7 leachate pumps in the new building pumped into the main building. The main building contained an 8th leachate pump along with a main holding tank and redundant main discharge pumps capable of operating independently or together as needed. The discharge pumps are controlled using a Variable frequency drive. The total discharge flow is regulated based upon the pressure reading in the discharge line in order to keep the flow within the permit limits as required by the local POTW.

The system is fully automated and adjusts automatically to the incoming flow changes due to rain events and the discharge limitations required by the POTW. The master control panel MCP allows the user to easily adjust the settings controlling the automated operation to meet any changes to the operating conditions as required by permit. The system allows for complete control from each of the on site buildings and also through remote computer access.