Pump Systems

Long Term Rental System at a rural GA Gas Station

Rental Systems have often become a preferred option for fund reimbursed cleanup sites.

Renting a system offers flexibility to adapt to site or funding changes. This offers regulators more control over site operations and provides a more predictable reimbursement cost. Also, since rental systems are already assembled, the time from purchase order to start up is much quicker.

The consultant has worked with MAE2 to provide several rental systems for site remediation. The consultant recommended a multi-phase groundwater pump and treat remediation system that incorporated down well groundwater pumps and high vacuum DPE (Dual Phase Extraction) in order to remove the free product and lower the dissolved phase gasoline concentrations.

The consultant has worked with MAE2 to provide several rental systems for site remediation. The consultant recommended a multi-phase groundwater pump and treat remediation system that incorporated down well groundwater pumps and high vacuum DPE (Dual Phase Extraction) in order to remove the free product and lower the dissolved phase gasoline concentrations.

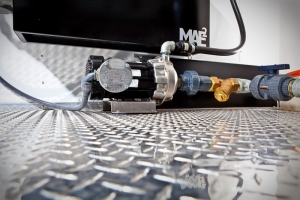

MAE2 provided a high vacuum rotary claw pump system and QED pneumatic auto pumps to dewater the wells and enhance the vacuum influence. The rotary claw vacuum pump was chosen to allow the system flexibility to operate at a wide range of vacuum levels. The flexibility allows the system to operate at low vacuum to help slurp the free product in the wells while pumping at a low rate to maximize the free product recovery. The vacuum can also be increased to maximize dewatering and dissolved phase recovery.

The 9 pneumatic auto pumps operate on demand with a 10 HP reciprocating air compressor providing the air supply needed for pumping. The Groundwater Treatment system consists of an air water separator, an oil water separator to remove free product and a poly stackable tray stripper to remove the dissolved phase gasoline and then pumped through bag filters plumbed in series and two high pressure steel carbon vessels for final treatment before discharge. The OWS pump and Air Stripper pump are centrifugal transfer pumps. An enclosed steel frame utility trailer maximizes flexibility and mobility.

The regulatory agency requires consistent run time for all approved systems. The system provides run time hours, vacuum trends, and water flow totals recorded through the PLC control panel. The cellular connection allows full system control and data through easy-to-use web browser access. The instant alarm notification and remote control allows the consultant to immediately respond to any changing site conditions and maximize system run time.

This Remediation System uses the following components and subsystems

Rotary Claw Vacuum Pump

Poly Stackable Tray Air Stripper

PLC Control panel

Oil Water Separator

Vapor Liquid Separator

Centrifugal Transfer Pump

Progressive Cavity Transfer Pump

Reciprocating Air Compressor

Down well Pneumatic Pumps

Leachate and Condensate Pumping Systems

If you need to dewater, move leachate, or pump contaminated groundwater, MAE2 has what you need. Choose from a wide range of electric and pneumatic pumps for any application.

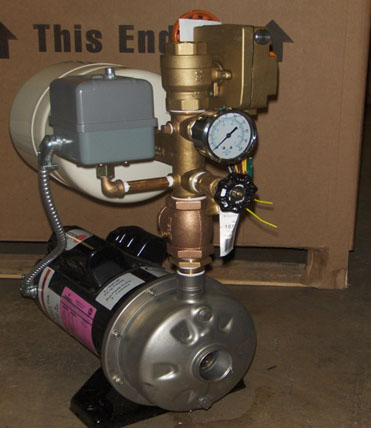

Centrifugal Transfer Pump Systems

Centrifugal pump systems are used to transfer liquids from sumps, pits, tanks and transfer stations.

These pumps come in a variety of horsepower and typically require 208-230/460 3 phase power. These pumps can be designed for low flow low head or high flow high head scenarios. Typical flow rates are 5-200 GPM with TDH ranges from 5-200. MAE2 can integrate centrifugal pumps as prepackages systems using common skid base, inlet and outlet pipe and fittings, instrumentation and local or remote control packages.

Pneumatic Pumping Systems

Pneumatic Free Product Recovery and Total Fluids Pumping Systems

Pneumatic submersible pumps, a type of downwell pump, are used to extract contaminated groundwater, leachate and free phase LNAPL and DNAPL. Each pump system uses air to displace the liquid and are safe in explosive hazardous locations. Pneumatic pump systems provide low to moderate flow rates typically from .5-8 GPM. MAE2 can provide turnkey pneumatic systems coupled with compressor, solenoids, level control, product drums, oil water separators and treatment packages.

Pneumatic Pump Water Treatment System

Electric Submersible Pumps

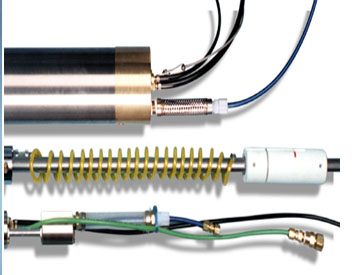

Electric submersible pumps,a type of downwell pump, are used to extracted groundwater and can be designed for low and high flow scenarios.

MAE2 can provide turnkey submersible pump packages with down well tubing, electrical cable, well head assemblies, instrumentation, valving and variable frequency drive controls packages.

Click to download MAE2 Electric Submersible Pumps data sheet

Pump Systems

MAE2 offers a wide range of pump systems from electric submersible and centrifugal units to pneumatic total fluids and free product recovery. Each pump system can be integrated into a recovery or treatment system or provided as a standalone unit. MAE2 also provides pre-engineered pneumatic and electric pump systems fully integrated with controls, piping and instrumentation.

Downwell Pumps

Electric Submersible Pumps

Pneumatic Pumping Systems

Transfer Pumps

Centrifugal Transfer Pump Systems

Progressive Cavity Pumps