Integrated Remediation Systems

Groundwater Pump and Treat Systems

Groundwater pump and treat systems utilize downwell pumps to remove contaminated groundwater and then treat it with above ground components. MAE2 offers a full range of electric and pneumatic groundwater pumps to fit your site needs. Custom design the water treatment to include oil water separators, sediment filtration, air stripping and media treatment as needed to meet your discharge requirements.

Pneumatic Pumping Systems

Electric Submersible Pumps

Centrifugal Transfer Pump Systems

Air Strippers

Rotary Claw Compressors

Oil Water Separators

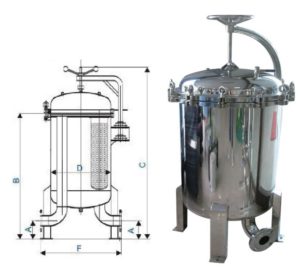

Multi-Bag/Cartridge Filter Vessels

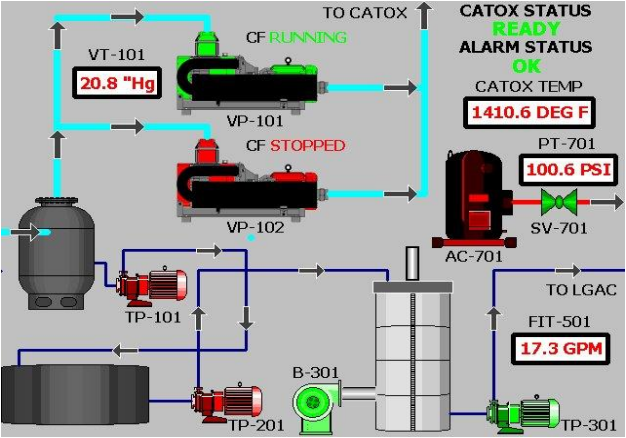

Dual-Phase Extraction Systems

Dual Phase Extraction (also called Multi-Phase Extraction) is the use of high vacuum system to remove both contaminated groundwater and soil vapor.

MAE2 designs high vacuum systems with water and vapor treatment customized to your site needs. Combine Oil or Water Sealed Liquid Ring pumps for high vacuum and high flow, low maintenance rotary claw pumps for medium to high vacuum and high flow, or rotary lobe positive displacement pumps for low and medium vacuum and high flow with your choice of water and vapor treatment equipment.

The high vacuum dual phase extraction process involves the subsurface removal of air, water, and product. The main determining factor behind the selection of the high vacuum blower is the expected operating vacuum level. Rotary Claw blowers and Liquid ring pumps are most suitable for vacuum levels of 20-29 inches mercury (Hg). Each Dual Phase Extraction System is manufactured to meet your design and site requirements.

Environmental Remediation Systems

MAE2’s turnkey solutions are custom designed for your site and application.

MAE2 has been designing and building cost effective remediation systems for over 20 years. Whether you need a simple skid mounted blower or a multiple enclosure system, MAE2 can provide a hassle free, on time solution.

Every system is…

- custom designed to your exact requirements and needs

- built to last with superior materials

- manufactured locally in our new South Carolina facility by a team of skilled professionals

- thoroughly tested prior to shipment to ensure ease and speed of start-up

- a cost-effective solution to all your site environmental remediation needs

Environmental Remediation Systems may include the following…

Industrial Process/Wastewater Treatment Systems

Industrial process requirements and discharge regulations demand custom designed, cost effective solutions.

MAE2 has integrated systems and components to meet your industrial process and wastewater applications.

MAE2 also provides solids and chemical treatment to reduce operating costs and maintain your discharge requirements. MAE2 offers turnkey process and wastewater systems and individual process components.

See examples of integrated systems in custom enclosures below.

Packaged Reverse Osmosis (RO) Water Treatment Systems

Take the expense and the mystery out of large-scale reverse osmosis plants (RO plants) with a packaged system. By making pre-designed, module-sized plants, fully assembled in standard 20-ft and 40-ft containers, the complexity and the construction of a building to house a water purification plant is no longer necessary.

Click the following link to download the RO Brochure

Wastewater systems often include…

Landfill, Gas and Chemical Treatment Systems

Landfills have challenging requirements that require removal and control of methane, leachate and potential groundwater contaminants.

MAE2 provides a full range of landfill gas removal, leachate pumping and chemical treatment systems.

Common treatment systems for remediation of contaminants may include…

Leachate and Condensate Pumping Systems

If you need to dewater, move leachate, or pump contaminated groundwater, MAE2 has what you need. Choose from a wide range of electric and pneumatic pumps for any application.

Methane Extraction Blowers

Methane extraction is required for safety and to comply with regulations. It is important to select the correct blower to maintain an even vacuum throughout your extraction area and to match the performance of your gas flare or burner. MAE2 can provide a cost effective integrated blower package designed for your application.

Rentals

See sample diagrams of the trailers here.

MAE RS 50339

Dual Phase Extraction/Groundwater Treatment

For sites with fuel or solvent plumes with slower recharge

- Duplex 7.5 HP rotary claw vacuum blowers 300 acfm @ 20” HG

- 90 gallon knockout with 1 HP progressive cavity pump

- 5 Leg DPE manifold

- 20 GPM carbon steel oil water separator with 1 HP centrifugal pump

- 4 tray 25 gpm rated poly airstripper with 3 HP pressure blower and 1.5 HP centrifugal pump

- Duplex # 2 size bag filter

- Duplex 500 Lb liquid phase carbon vessels

- PLC control panel with operator interface and sensaphone autodialler

- 8’ x 28’ enclosed tandem axle trailer with man door and barn style rear doors

MAE RS 22357

Dual Phase Extraction/Groundwater Treatment

For sites with fuel or solvent plumes with slower recharge

- Duplex 7.5 HP rotary claw vacuum blowers 300 acfm @ 20” HG

- 120 gallon knockout with 1 HP progressive cavity pump

- 8 Leg DPE manifold

- 20 GPM stainless steel oil water separator with 3/4 HP centrifugal pump

- 4 tray 40 gpm rated poly airstripper with 3 HP pressure blower and 1.5 HP centrifugal pump

- Duplex # 2 size bag filter

- Duplex 500 Lb liquid phase carbon vessels

- PLC control panel with operator interface and wireless telemetry

- 8’ x 24’ enclosed tandem axle trailer with man door and barn style rear doors

MAE RS 12784

Dual Phase Extraction/Pump and Treat/Groundwater Treatment/Air Sparge

For sites with gasoline or solvent plumes with high recharge or deep wells. Air Sparge improves vadose zone remediation through volatilization and bio stimulation

- Duplex 15 HP rotary claw vacuum blowers 700 acfm @ 20” HG

- 120 gallon knockout with 2 HP progressive cavity pump

- 11 Leg DPE manifold

- 8 Leg well pump water return manifold

- 40 GPM stainless steel oil water separator with 2 HP centrifugal pump

- 4 tray 40 gpm rated poly airstripper with 3 HP pressure blower and 2 HP centrifugal pump

- Duplex # 2 size bag filter

- Duplex 500 Lb liquid phase carbon vessels

- 15 HP Sparge compressor 165 cfm @ 20 psi with 1 HP heat exchanger

- 9 Leg sparge manifold

- EOS control panel with land line telemetry

- Relay sub panel for 8 electric submersible pumps

- 8’ x 28’ enclosed tandem axle trailer with man door and barn style rear doors

MAE RS 23892

Dual Phase Extraction/Pump and Treat/Groundwater Treatment

For sites with gasoline or solvent plumes with high recharge or deep wells.

- 40 HP Liquid Ring vacuum pump 500 acfm @ 20” HG

- 220 gallon knockout with 2 HP progressive cavity pump

- 13 Leg DPE manifold

- 13 Leg well pump water return manifold

- 40 GPM stainless steel oil water separator with 2 HP centrifugal pump

- 4 tray 40 gpm rated poly airstripper with 3 HP pressure blower and 3 HP centrifugal pump

- Duplex # 2 size bag filter

- Duplex 500 Lb liquid phase carbon vessels

- 15 HP compressor 55 cfm @ 100 psi

- 13 Leg air supply manifold manifold

- 13 Top Loading pneumatic pumps

- PLC based controls with color OIT and wireless telemetry

- 8’ x 28’ enclosed tandem axle trailer with man door and barn style rear doors

MAE RS 50445

Air Sparge/Soil Vapor Extraction

For sites with low dissolved phase gasoline or solvent plumes where the goal is to remediate the vadose zone and saturated soils without extracting groundwater

- 7.5 HP rotary claw vacuum blower 170 ACFM @ 22” HG

- 90 gallon knockout with 1 HP transfer pump

- 4 point SVE manifold

- 150 gallon holding tank with high level alarm

- 20 HP rotary claw sparge compressor 75 cfm @ 30 psi

- 1 HP heat exchanger

- 6 point sparge manifold

- PLC control panel with color OIT and wireless telemetry

- 7.5’ x 12’ Tandem axle enclosed trailer with man door and rear barn double doors

MAE RS 22175

Air Sparge/Soil Vapor Extraction

For sites with low dissolved phase gasoline or solvent plumes where the goal is to remediate the vadose zone and saturated soils without extracting groundwater

- 20 HP PD blower 250 SCFM @ 10” HG VFD controlled

- 120 gallon knockout with high level switch

- 20 HP rotary screw sparge compressor with 100 gallon receiver tank

- 12 point sparge manifold

- 8’ x 18’ 2 room enclosed trailer with man door and double rear barn style doors

- EOS based control panel with land line telemetry

MAE RS 12022

Air Sparge/Soil Vapor Extraction

For sites with low dissolved phase gasoline or solvent plumes where the goal is to remediate the vadose zone and saturated soils without extracting groundwater

- 15 HP Regenerative Blower 200 SCFM @ 6” Hg

- 120 gallon knockout tank with 1 HP transfer pump

- 25 HP Rotary screw sparge compressor 100 cfm @ 50 psi

- 8 point sparge manifold

- 6’ x 18’ 2 room enclosed trailer with man door and double rear barn style doors

- Relay based controls panel with autodialler

MAE RS 50304

Soil Vapor Extraction/Oxidizer

For sites with low dissolved phase gasoline or solvent plumes where the goal is to remediate the vadose zone and saturated soils without extracting groundwater and the vapors are treated to meet air permitting requirements

- 15 HP Regenerative blower 350 SCFM @ 80” wc VFD controlled

- 120 gallon knockout tank with ¾ HP transfer pump

- Falco 300 electric oxidizer with process control valve

- 7’ x 16’ open deck tandem axle trailer

- Relay based control panel with Oxidizer interlocks

Oil Water Separators

Corrugated Plate Oil Water Separators (OWS) are used to enhance the separation of petroleum and oils in free phase or dispersed non dissolved droplets from water.

Our lines of OWSs are manufactured to API 421 guidelines and each separator is customer designed to your specific application using a variety of separation media and material of construction.

Standard Systems

Standard systems are constructed from marine grade aluminum or stainless steel with flow rates from 10-1000 GPM. Media options include PVC and Polypropylene style corrugated plate packs. Each separator is designed with universal fittings allowing the operator to remove and reinstall the lid to change the inlet/outlet orientation of the tank. Each OWS includes separation chamber, adjustable skimmer, overflow weir, pump out chamber, V Hopper, hinged gasketed lid, lid springs and standard inlet/outlet and drain fittings.

Custom Systems

Custom separators can be built to your specification using a wide variety of materials and design options. A full 3 CAD drawing will be provided to you for approval prior to construction.

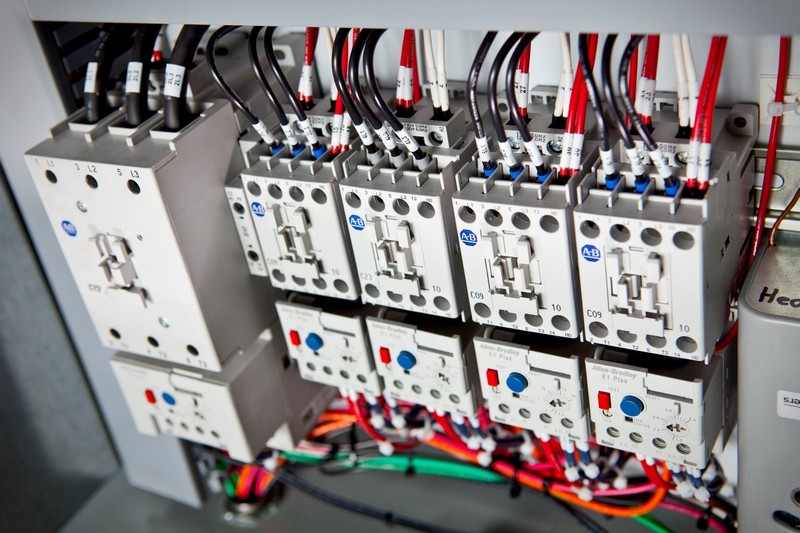

Controls

Relay-Based and PLC Controls

MAE2 manufactures relay-based and PLC panels used for instrumentation and flow control, chemical feed applications, pump stations, blower packages, groundwater remediation systems, and water/waste water processes.

These are just a few of the applications for which we can help you. We can combine soft starters, variable frequency drives, process meters and any other device you may require to complete your package.

We have extensive experience working with Allen-Bradley, General Electric, Siemens and Modicon platforms and we possess several programming and configuration software packages to assist us in the engineering and development of your project. Our automated control systems can be designed to provide data acquisition, real time process monitoring, and custom report configuration. The information that you require can be accessible from the system panel, front office or remote location.

MAE2 utilizes both IEC and NEMA devices and our control packages are built to follow the guidelines put forth in the NEC, NFPA79 and UL508A.

Standard Features

- Lockable Nema IV Enclosure

- Inner Swing Out Door

- Illuminated Hand/Off/Auto Switches

- Red Alarm Light Indicators

- Phase Monitors

- Surge Protection

- IEC Contactors And Motor Protectors

- Short Circuit Protection

- Full Documentation with

- Load Summary

- Loop Description

- Components List

- Electrical Drawings

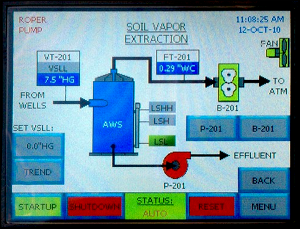

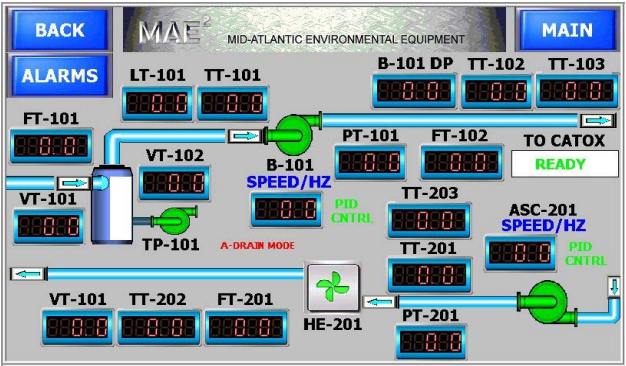

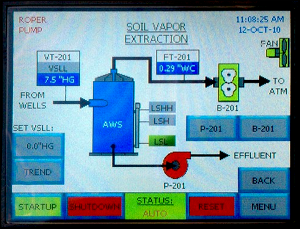

Remote Monitoring

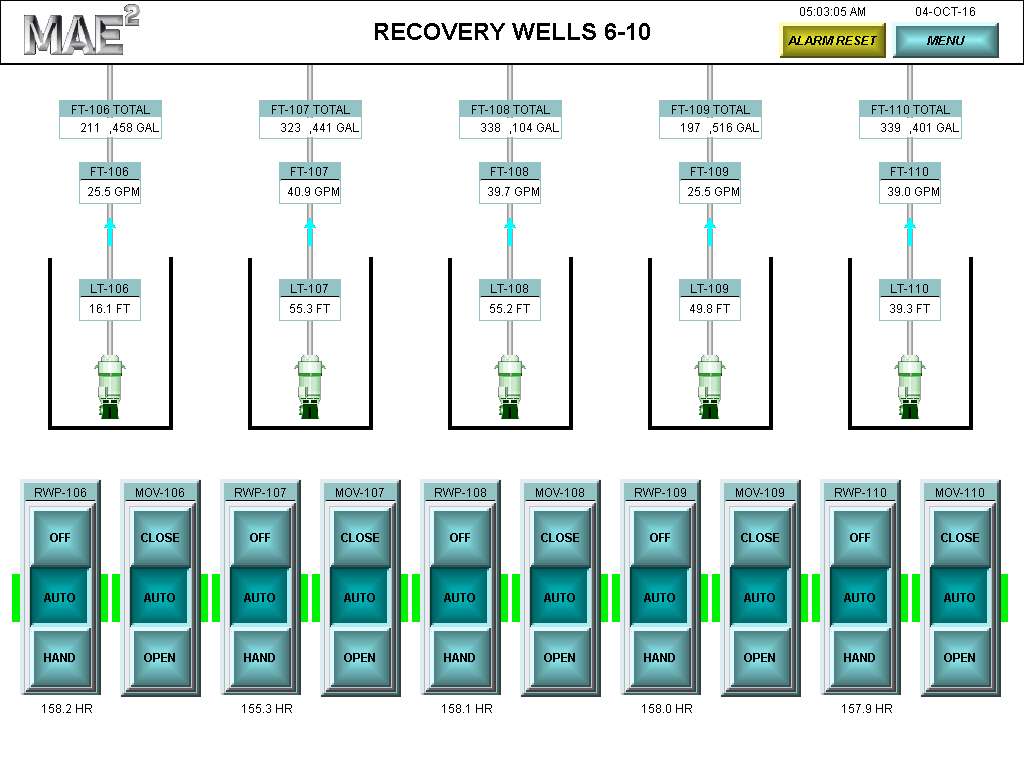

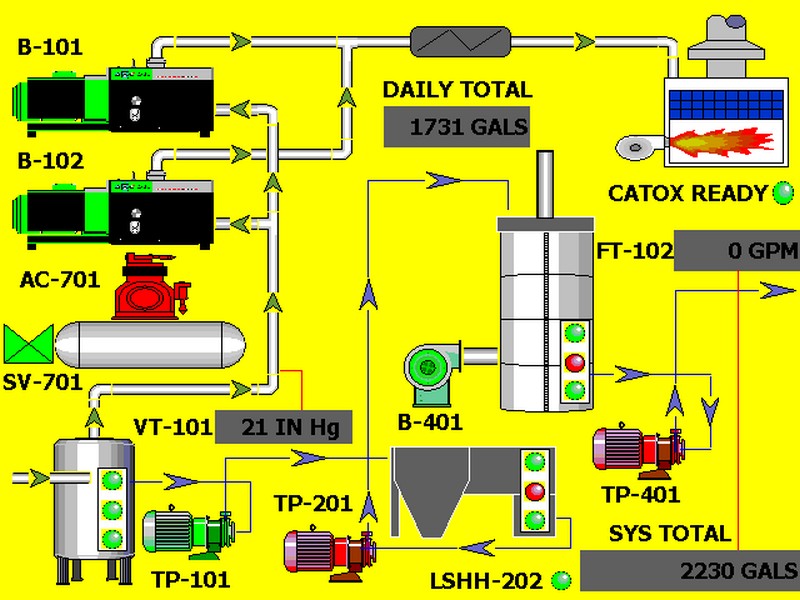

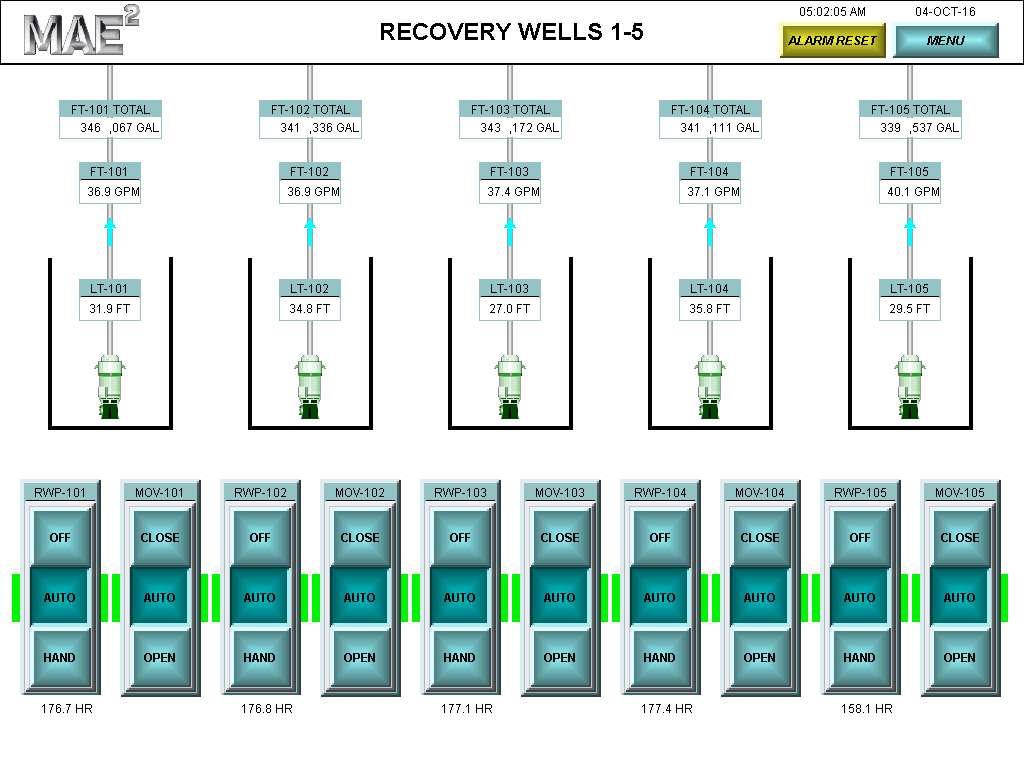

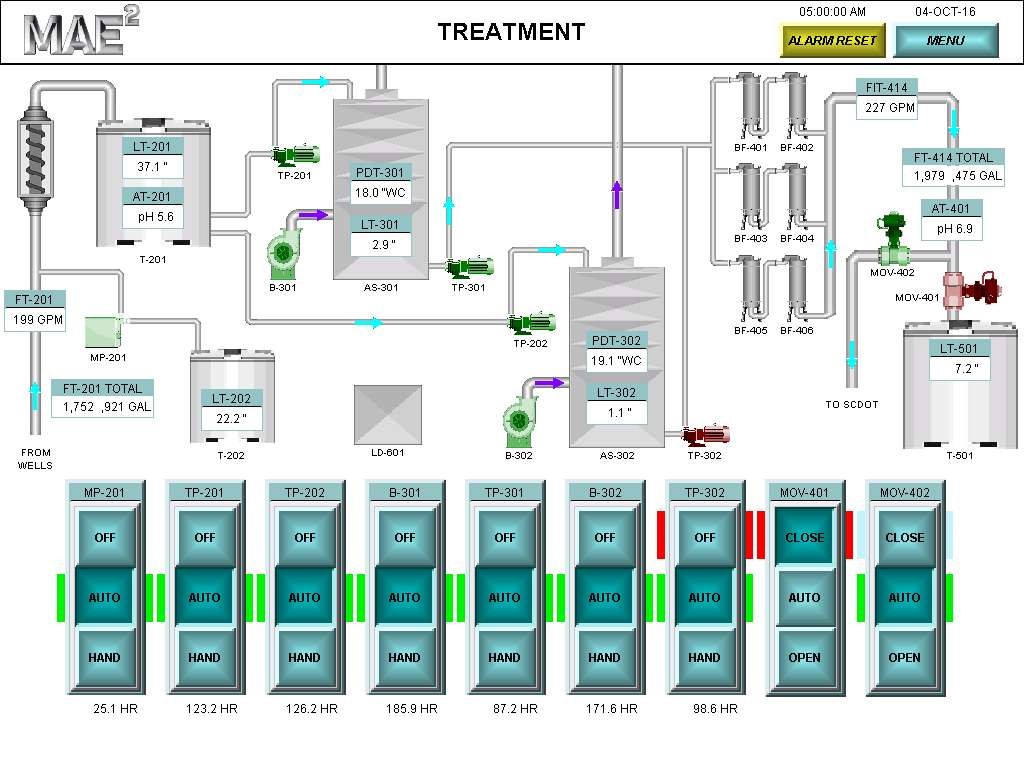

MAE2 understands the need to access, monitor and control systems. Modern PLC controls allow for onsite touch screen operation and performance monitoring on site or via the internet.

Remote access allows you to record performance data like run time hours, pressures, temperatures and flows right from your computer or smart phone. You can reset alarms, restart or shut down your equipment without having to travel to the site, saving time and money. Full color displays on site or on your computer make operation and control simple and cost effective.

Remote access allows you to record performance data like run time hours, pressures, temperatures and flows right from your computer or smart phone. You can reset alarms, restart or shut down your equipment without having to travel to the site, saving time and money. Full color displays on site or on your computer make operation and control simple and cost effective.

Air Strippers

Air Strippers are used to remove volatile organic compounds (VOC) from groundwater and process water with removal efficiencies up to 99%. These air strippers are engineered to serve in small water treatment projects or larger, process-type projects involving multiple treatment stages. They can act as a pre-treatment stage for other process elements, such as large aerobic bio-treatment units, removing VOCs at much lower airflow rates to reduce the costs of off-gas treatment.

Click for downloadable PDF of MAE2 Air Strippers Datasheet

Removable Tray Air Strippers

Removable tray air strippers are the only high-performance strippers with lightweight stainless steel body and front-slide out trays. They provide many advantages such as one-person cleaning, front serviceability and forced-draft air bubble technology. With flow rates range from 25-1000 GPM the removable tray low profile design allows them to be installed in mobile trailer, buildings and steel base skids.

Stackable Tray Air Strippers

The unique configuration consists of a series of integrally-molded shell/tray modules. The multiple sieve tray design uses forced-draft air bubble generation to provide rapid, effective VOC removal (up to 99%).

Every element of the heavy-duty HDPE construction has been engineered for durable, reliable performance with a multi-step positive seal against leakage.

Models are sized and priced to be the most economical choice for many low to moderate flow cleanup applications (up to 40 GPM-Poly Construction). Low capital expense and low O and M requirements make the difference.

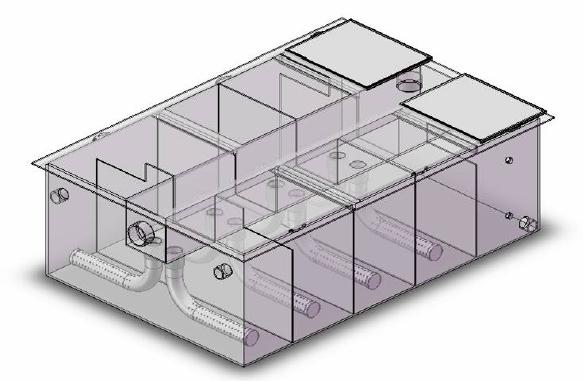

Diffused Aerator Air Strippers

Diffused Aerators can achieve 99% removal efficiency and use a serpentine pattern designed aerated chamber. A blower provides the required air through proprietary fine or coarse bubble diffusers. The water then cascades into the last quiescent chamber and out of the system. Air stripping of the contaminant is achieved in the aerated chambers without media or moving parts. It is a compact, low maintenance, and low cost alternative to filters, packed towers, and mechanical aerators for the fast and efficient removal of dissolved gases and volatile organic.

Click to Download Air Stripper PDF

Air Sparging Systems

Air Sparging involves the injection of air or gases to the subsurface that promote enhanced degradation of contamination.

Sparge systems are designed based on required air flow and anticipated breakthrough pressure. A wide variety of blowers and compressors can be used to achieve various flow and pressure scenarios. Typical industry standards include Rotary Vane, Rotary Claw and Rotary Screw compressors.

Typical systems include discharge particulate and oil coalescing filtration to minimize oil and particulate carry over to the subsurface. In addition, a receiver tank should be installed to buffer the compressor from changes in air demand.

Typical systems include blower or compressor, TEFC or XP motor, heat exchanger if required and a prewired, pretested, custom NEMA IV control panel. Pressure gauges, flow indicators, temperature indicators and filtration can be specified per your application.

All Air Sparge Sparging components are fully integrated and prewired on a steel skid with optional custom sound attenuating enclosure. Air Sparging Systems are easily integrated with new or existing Soil Vapor Extraction Systems.

Options

- Manifolds with regulators, flow indicators and gauges

- Heat Exchanger

- Ozone Generators

- Oxygen Generators

- Remote telemetry system monitoring and alarm notification