Environmental Remediation Systems

Long Term Rental System at a rural GA Gas Station

Rental Systems have often become a preferred option for fund reimbursed cleanup sites.

Renting a system offers flexibility to adapt to site or funding changes. This offers regulators more control over site operations and provides a more predictable reimbursement cost. Also, since rental systems are already assembled, the time from purchase order to start up is much quicker.

The consultant has worked with MAE2 to provide several rental systems for site remediation. The consultant recommended a multi-phase groundwater pump and treat remediation system that incorporated down well groundwater pumps and high vacuum DPE (Dual Phase Extraction) in order to remove the free product and lower the dissolved phase gasoline concentrations.

The consultant has worked with MAE2 to provide several rental systems for site remediation. The consultant recommended a multi-phase groundwater pump and treat remediation system that incorporated down well groundwater pumps and high vacuum DPE (Dual Phase Extraction) in order to remove the free product and lower the dissolved phase gasoline concentrations.

MAE2 provided a high vacuum rotary claw pump system and QED pneumatic auto pumps to dewater the wells and enhance the vacuum influence. The rotary claw vacuum pump was chosen to allow the system flexibility to operate at a wide range of vacuum levels. The flexibility allows the system to operate at low vacuum to help slurp the free product in the wells while pumping at a low rate to maximize the free product recovery. The vacuum can also be increased to maximize dewatering and dissolved phase recovery.

The 9 pneumatic auto pumps operate on demand with a 10 HP reciprocating air compressor providing the air supply needed for pumping. The Groundwater Treatment system consists of an air water separator, an oil water separator to remove free product and a poly stackable tray stripper to remove the dissolved phase gasoline and then pumped through bag filters plumbed in series and two high pressure steel carbon vessels for final treatment before discharge. The OWS pump and Air Stripper pump are centrifugal transfer pumps. An enclosed steel frame utility trailer maximizes flexibility and mobility.

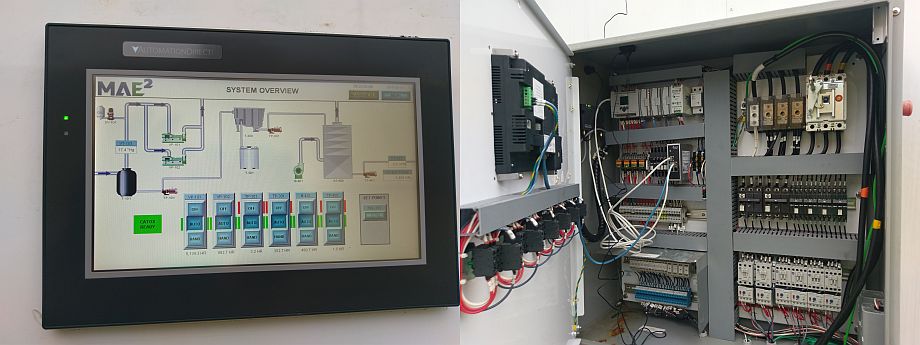

The regulatory agency requires consistent run time for all approved systems. The system provides run time hours, vacuum trends, and water flow totals recorded through the PLC control panel. The cellular connection allows full system control and data through easy-to-use web browser access. The instant alarm notification and remote control allows the consultant to immediately respond to any changing site conditions and maximize system run time.

This Remediation System uses the following components and subsystems

Rotary Claw Vacuum Pump

Poly Stackable Tray Air Stripper

PLC Control panel

Oil Water Separator

Vapor Liquid Separator

Centrifugal Transfer Pump

Progressive Cavity Transfer Pump

Reciprocating Air Compressor

Down well Pneumatic Pumps

Rural GA Convenience Store Remediation Site

MAE2 was selected to design and build a Multi Phase Extraction and Groundwater Treatment remediation system for a convenience store site in rural GA.

The consultant was tasked with removing free product which was part of a long narrow plume between the tanks and the gas pump island.

The consultant and MAE2 chose a high vacuum system that could treat extracted groundwater at 15-20 GPM and to remove large amounts of free product gasoline. MAE2 used this data to design a system that would extract and treat groundwater and free product from 6 vacuum wells located on site. The water needed to be treated to meet NPDES limits and was discharged into a roadside ditch.

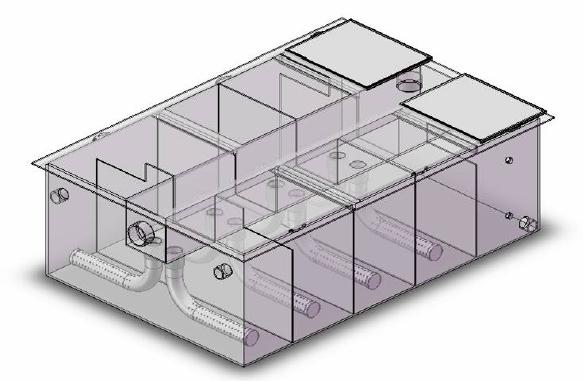

The system uses 2 high vacuum rotary claw pumps, providing over 500 ACFM flow at 25” HG vacuum, to extract impacted groundwater and vapors. The client prefers to use multiple pumps operating in parallel rather than a single large pump. This design provides more flexibility to save energy as site needs change over time, along with redundancy to reduce downtime. The system uses a 6 point custom inlet manifold and a marine grade aluminum 120 gallon Air Water Separator.

A progressive cavity transfer pump is used to pump the water to a 20 GPM Oil Water Separator to remove any free product gasoline. A 55 gallon drum with a high level alarm is used as a Product Storage Tank. Progressive Cavity pumps are selected because they do not create the chemical emulsification of the gasoline and water that other pumps cause. After the Oil Water Separator removes the free product a centrifugal transfer pump sends the water to a Poly Stackable Tray Air Stripper to remove dissolved phase gasoline. The water is pumped through bag filters, with valves allowing them to be used in parallel or series, to remove solids and particles from the water. Finally the water passes through two Steel High Pressure 250 LB Liquid Carbon Vessels before being discharged to a roadside ditch.

The custom integrated PLC control panel provides runtime hours, vacuum trends, temperature, carbon vessel pressure and water flow totals. The controls use two Variable Frequency Drives (VFD) to convert from 240, single phase power to 240, 3 phase power to operate the system motors.

VFD’s allow users to adjust motor speeds and reduce/save energy. The system uses a cellular data connection allowing full system control and data access through easy to use web browser access. The data allows easy access to system operational status and the data needed for writing reports as required by the regulators.

This Remediation System uses the following components and subsystems:

Environmental Remediation System Finds New life at a New Site.

Reuse of an Existing Remediation System results in significant savings and reduced training time.

Many consulting firms have possession of existing remediation systems that have been used to complete the remediation at a site and achieve site closure. Reusing that system on a new site can save cost and increase the bottom line for the consulting firm. Additionally, the field operators are already familiar with the system maintenance and operation. MAE2 has helped many consultants update and refurbish existing systems to help them maximize their resources and provide more competitive solutions to their clients

MAE2 was recently contracted by a consultant to refurbish a used system from their inventory to prepare it and customize it for use at a new site. The refurbished system allowed the consultant to use a system they were familiar with while keeping the budget within approved funding levels.

The system was transported to our manufacturing facility. The MAE2 technical staff thoroughly tested the system and inspected each component. All required maintenance was performed and any components and parts that were beyond their useful life, due to wear and tear, were replaced or upgraded.

The system and controls were customized to meet the requirements of the new site. The end result was a customized, reliable system at a considerable savings when compared to a brand new system. Additionally the consultant’s field staff was already familiar with the system, which greatly reduced labor and training time and costs.

The system is a Dual Phase Extraction and Groundwater Treatment system designed for 10 GPM water flow and 500 ACFM vapor flow at 25” HG. There is a 5 point extraction manifold that pulls both water and vapor from the extraction wells using two 10 HP rotary claw vacuum pumps in parallel. The extracted groundwater is collected in the 120 G Vapor/Liquid separator and then pumped to an Oil Water Separator using a progressive cavity transfer pump. Any free fuel that is extracted is collected in the OWS gravity drains into a product holding tank.

The water is pumped using a centrifugal transfer pump into the Poly Stack-able Tray Air Stripper. The Pressure Blower forces air through the air stripper trays removing over 99% of the dissolved fuel from the water. The water is then pumped through two bag filters in parallel and one high pressure steel carbon vessels for final polishing treatment before discharge. The Air Stripper uses another centrifugal transfer pump to pump the water through the bag filters, carbon and to the final discharge point. The system is controlled by a newly upgraded custom PLC control panel that allows for remote access and control using web-based telemetry.

Components used in this system

Progressive Cavity Transfer Pump

Poly Stack-able Tray Air Stripper

Pressure Blower

Bio Remediation Systems

Bio Remediation Systems include Aerobic Bioremediation, Anaerobic Dechlorination and Bio Augmentation.

Aerobic Bioremediation Systems

Aerobic Bioremediation Systems are designed to deliver high volumes of dissolved oxygen and hydrocarbon degrading bacteria and nutrients to treat hydrocarbon contaminated sites. The systems provide consistent recirculation of oxygen-rich, nutrient-rich water to provide the critical requirements needed for successful in situ bioremediation. This recirculation provides the appropriate oxygen and nutrient volumes required to degrade the contaminant mass and continuous movement of the amendments throughout the site to provide maximum contact with the contaminated soils. These units can be stand alone or fully integrated into an existing or new Multi Phase Extraction System or Pump and Treat System.

Anaerobic Dechlorination Systems

Anaerobic Dechlorination Systems are designed to deliver substrates and nutrients to create the ideal site conditions for complete dechlorination of TCE, PCE, DCE and VC. The systems provide recirculation of the amended water throughout the site for maximum contact with the contaminated soils. The continuous operation allows for the correct mass delivery, and distribution to prevent biofouling and allow for complete dechlorination without stalling.

Bio Augmentation

Bio Augmentation (biologically enhanced recirculation) involves the injection and recirculation of bacteria, nutrients or substrates to create an active, balanced environment in the subsurface that biologically degrades and eliminates the contamination. MAE2 can help design fully automated and manual recirculation equipment for enhanced Bio remediation for gasoline and chlorinated solvent sites.

Aerobic Bioremediation Systems

Aerobic Bioremediation Systems are designed to deliver high volumes of dissolved oxygen and hydrocarbon degrading bacteria and nutrients to treat hydrocarbon contaminated sites. The systems provide consistent recirculation of oxygen-rich, nutrient-rich water to provide the critical requirements needed for successful in situ bioremediation. This recirculation provides the appropriate oxygen and nutrient volumes required to degrade the contaminant mass and continuous movement of the amendments throughout the site to provide maximum contact with the contaminated soils. These units can be stand alone or fully integrated into an existing or new Multi Phase Extraction System or Pump and Treat System.

Bio Augmentation

Bio Augmentation (biologically enhanced recirculation) involves the injection and recirculation of bacteria, nutrients or substrates to create an active, balanced environment in the subsurface that biologically degrades and eliminates the contamination. MAE2 can help design fully automated and manual recirculation equipment for enhanced Bio remediation for gasoline and chlorinated solvent sites.

Air Strippers

Air Strippers are used to remove volatile organic compounds (VOC) from groundwater and process water with removal efficiencies up to 99%. These air strippers are engineered to serve in small water treatment projects or larger, process-type projects involving multiple treatment stages. They can act as a pre-treatment stage for other process elements, such as large aerobic bio-treatment units, removing VOCs at much lower airflow rates to reduce the costs of off-gas treatment.

Click for downloadable PDF of MAE2 Air Strippers Datasheet

Removable Tray Air Strippers

Removable tray air strippers are the only high-performance strippers with lightweight stainless steel body and front-slide out trays. They provide many advantages such as one-person cleaning, front serviceability and forced-draft air bubble technology. With flow rates range from 25-1000 GPM the removable tray low profile design allows them to be installed in mobile trailer, buildings and steel base skids.

Stackable Tray Air Strippers

The unique configuration consists of a series of integrally-molded shell/tray modules. The multiple sieve tray design uses forced-draft air bubble generation to provide rapid, effective VOC removal (up to 99%).

Every element of the heavy-duty HDPE construction has been engineered for durable, reliable performance with a multi-step positive seal against leakage.

Models are sized and priced to be the most economical choice for many low to moderate flow cleanup applications (up to 40 GPM-Poly Construction). Low capital expense and low O and M requirements make the difference.

Diffused Aerator Air Strippers

Diffused Aerators can achieve 99% removal efficiency and use a serpentine pattern designed aerated chamber. A blower provides the required air through proprietary fine or coarse bubble diffusers. The water then cascades into the last quiescent chamber and out of the system. Air stripping of the contaminant is achieved in the aerated chambers without media or moving parts. It is a compact, low maintenance, and low cost alternative to filters, packed towers, and mechanical aerators for the fast and efficient removal of dissolved gases and volatile organic.

Click to Download Air Stripper PDF

Air Sparging Systems

Air Sparging involves the injection of air or gases to the subsurface that promote enhanced degradation of contamination.

Sparge systems are designed based on required air flow and anticipated breakthrough pressure. A wide variety of blowers and compressors can be used to achieve various flow and pressure scenarios. Typical industry standards include Rotary Vane, Rotary Claw and Rotary Screw compressors.

Typical systems include discharge particulate and oil coalescing filtration to minimize oil and particulate carry over to the subsurface. In addition, a receiver tank should be installed to buffer the compressor from changes in air demand.

Typical systems include blower or compressor, TEFC or XP motor, heat exchanger if required and a prewired, pretested, custom NEMA IV control panel. Pressure gauges, flow indicators, temperature indicators and filtration can be specified per your application.

All Air Sparge Sparging components are fully integrated and prewired on a steel skid with optional custom sound attenuating enclosure. Air Sparging Systems are easily integrated with new or existing Soil Vapor Extraction Systems.

Options

- Manifolds with regulators, flow indicators and gauges

- Heat Exchanger

- Ozone Generators

- Oxygen Generators

- Remote telemetry system monitoring and alarm notification