Remediation Site of a Former Gas Station in a Rural Area

MAE2 was selected to design and build a remediation system for a retail gas station based upon the results of a pilot study.

The site is located in a very rural area and only single phase electrical power is available. MAE2 included a Rotary Phase Converter to convert the power to the three phase power needed to operate the larger motors. The site needed three phase voltage in order to meet the NEC, Class 1 Div 2 environment required for equipment operating in the potentially explosive environment created by removing and treating gasoline vapors

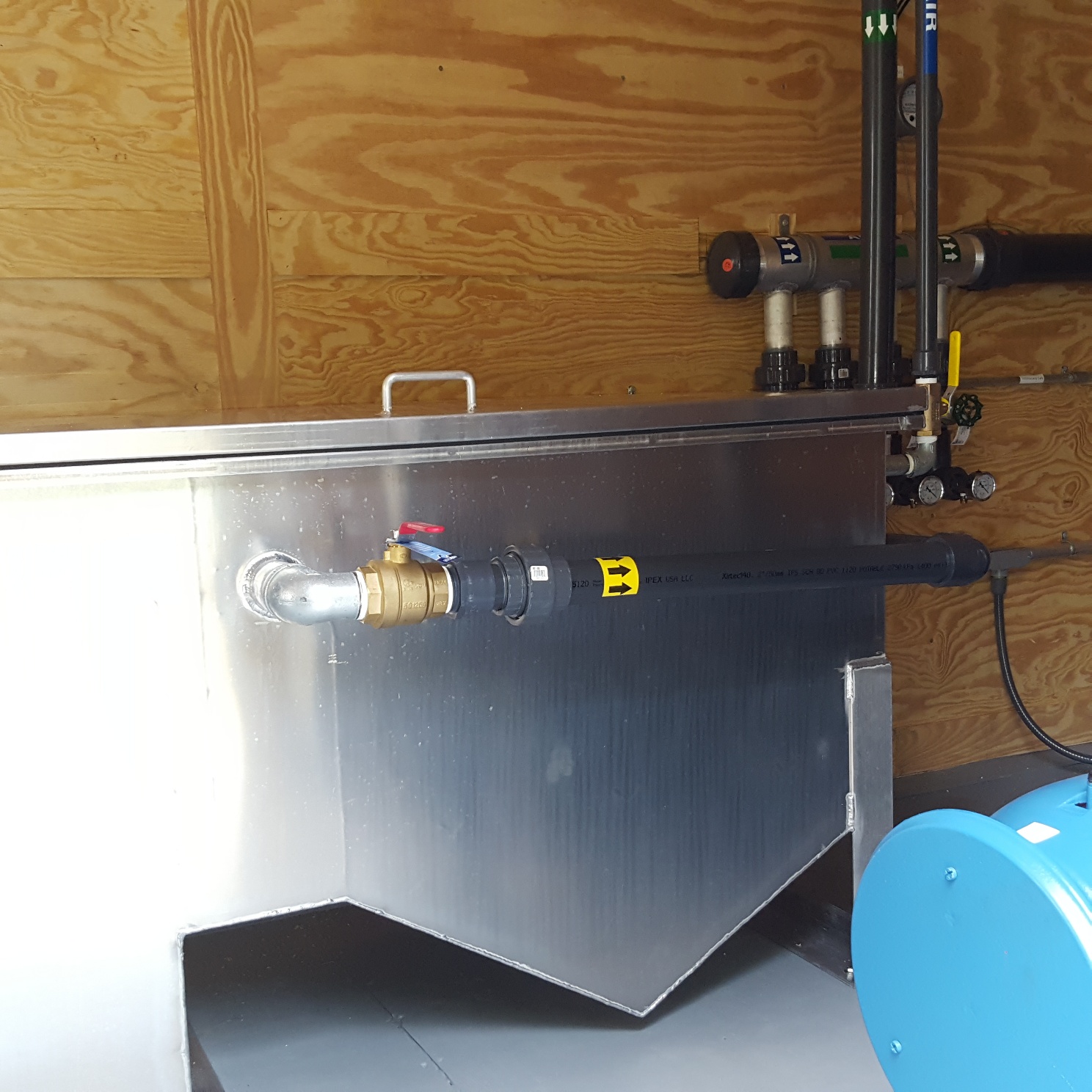

MAE2 used the pilot test data to design and provide written specifications for a Multi Phase Extraction and Groundwater Treatment system. The system will use a high vacuum rotary claw pump to extract impacted groundwater and vapors. The groundwater will be treated with an oil water separator to remove free product and then pass through an air stripper and liquid phase carbon to treat the dissolved phase gasoline.

Finally, the system will provide run time hours, vacuum trends, and water flow totals recorded through the PLC control panel. The cellular connection allows full system control and data through easy-to-use web browser access.