com

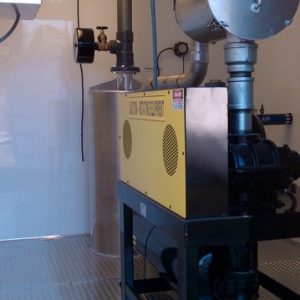

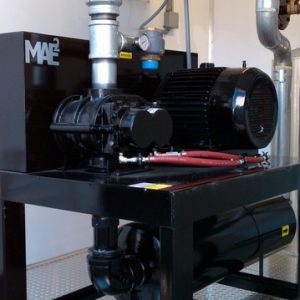

Positive Displacement Blowers

Extraction Manifolds

Diffused Aerator Air Strippers

Diffused Aerators can achieve 99% removal efficiency and use a serpentine pattern designed aerated chamber. A blower provides the required air through proprietary fine or coarse bubble diffusers. The water then cascades into the last quiescent chamber and out of the system. Air stripping of the contaminant is achieved in the aerated chambers without media or moving parts. It is a compact, low maintenance, and low cost alternative to filters, packed towers, and mechanical aerators for the fast and efficient removal of dissolved gases and volatile organic.

Click to Download Air Stripper PDF

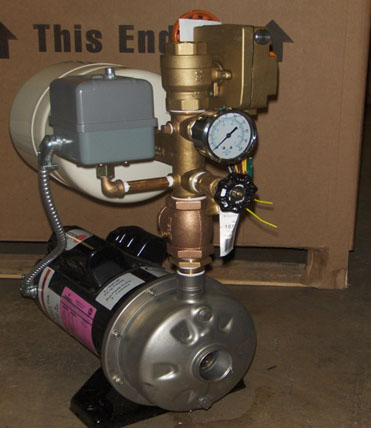

Centrifugal Transfer Pump Systems

Centrifugal pump systems are used to transfer liquids from sumps, pits, tanks and transfer stations.

These pumps come in a variety of horsepower and typically require 208-230/460 3 phase power. These pumps can be designed for low flow low head or high flow high head scenarios. Typical flow rates are 5-200 GPM with TDH ranges from 5-200. MAE2 can integrate centrifugal pumps as prepackages systems using common skid base, inlet and outlet pipe and fittings, instrumentation and local or remote control packages.

Pneumatic Pumping Systems

Pneumatic Free Product Recovery and Total Fluids Pumping Systems

Pneumatic submersible pumps, a type of downwell pump, are used to extract contaminated groundwater, leachate and free phase LNAPL and DNAPL. Each pump system uses air to displace the liquid and are safe in explosive hazardous locations. Pneumatic pump systems provide low to moderate flow rates typically from .5-8 GPM. MAE2 can provide turnkey pneumatic systems coupled with compressor, solenoids, level control, product drums, oil water separators and treatment packages.

Pneumatic Pump Water Treatment System

Electric Submersible Pumps

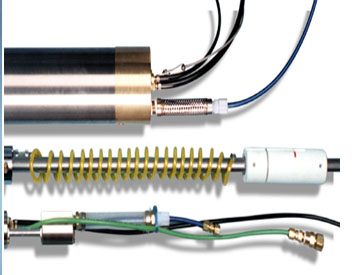

Electric submersible pumps,a type of downwell pump, are used to extracted groundwater and can be designed for low and high flow scenarios.

MAE2 can provide turnkey submersible pump packages with down well tubing, electrical cable, well head assemblies, instrumentation, valving and variable frequency drive controls packages.

Click to download MAE2 Electric Submersible Pumps data sheet

Electric Oxidizers

Electric oxidizer achieve destruction temperature using internal heaters to raise the temperature of catalyst blocks.

These units are compact and available with flow rates from 100-600 SCFM and require 208-230/460 V 3 phase power to operate. Standard features include stainless steel construction, process control valve, integrated control panels and exhaust stack extension. Extraction or process blowers can be added onto the skid and integrated to the inlet to provide a turnkey extraction destruction system. MAE2 can provide new, used or rental systems designed to meet your site specific needs.

Gas Fired Thermal and Catalytic Oxidizers

Gas fired oxidizers use propane or natural gas as a supplemental fuel source to achieve destruction temperatures.

These systems are available with flow rates from 100-2500 SCFM. Traditional thermal units destruct vapor via flame incinerations while catalytic units use a heated precious metal block. The systems can be design to be converted from Thermal to Catalytic mode and are easily retrofitted in the field. MAE2 can provide new, used or rental units designed for your specific site needs.

Vapor Liquid Separators

Regardless of the vacuum blower chosen, a vapor liquid separator should always be installed inline prior to the blower to capture extracted liquid and minimize on liquid carry over to the blower inlet.

Vapor Liquid Separators are sized based on air flow rates and retention time. At a minimum the VLS should include an inlet filter, ambient air dilution valve with control valve, discharge demister element, discharge pump with controls, and instrumentation – vacuum / pressure / temperature gauges.

Click to download MAE2 Vapor Liquid Separator Tanks data sheet

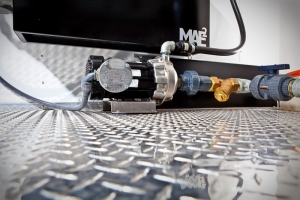

Liquid Ring Pump Systems

LRPs should be coupled with an inlet particulate filter-Integral seal oil reservoir with low oil level switch, coalescing air-oil separator element, pressure gauge, and sight glass air cooled seal oil heat exchanger with temperature control valve, high temperature switch and vacuum relief valve.