Pumps

System for Ground Water Remediation at a Power Generation Plant

MAE2 was asked to provide a system based upon detailed written specifications for a Multi Phase Extraction and Groundwater Treatment system. The system is located at a power generation facility.

The detailed specification required that the system be constructed to meet explosion proof NEC Class 1 Division 1 standards. The entire system had to be inspected approved and labeled by MET Labs. The system uses a Busch high vacuum rotary claw pump to extract impacted groundwater and vapors.

The detailed specification required that the system be constructed to meet explosion proof NEC Class 1 Division 1 standards. The entire system had to be inspected approved and labeled by MET Labs. The system uses a Busch high vacuum rotary claw pump to extract impacted groundwater and vapors.

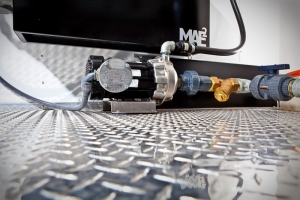

The groundwater is collected in a marine grade aluminum vapor liquid separator and a progressive cavity pump moves the liquids to an oil water separator. Any free product is removed and then a centrifugal pump moves the liquid through liquid phase carbon to treat the dissolved phase gasoline. The system is assembled in an 8’ X 20’ once through land sea container that has been customized with framed interior walls, R13 insulation and a 3200W heater.

Finally, the system will provide run time hours, vacuum trends, and water flow totals recorded through the PLC control panel.

The cellular connection allows full system control and data through easy-to-use web browser access. The instant alarm notification and remote control allows the consultant to immediately respond to any changing site conditions and maximize system run time.

This remediation system uses the following components and subsystems

Rotary Claw Vacuum Pump

PLC Control panel

Bag Filter

Carbon Filtration

Oil Water Separator

Vapor Liquid Separator

Centrifugal Transfer Pump

Progressive Cavity Transfer Pump

Leachate and Condensate Pumping Systems

If you need to dewater, move leachate, or pump contaminated groundwater, MAE2 has what you need. Choose from a wide range of electric and pneumatic pumps for any application.

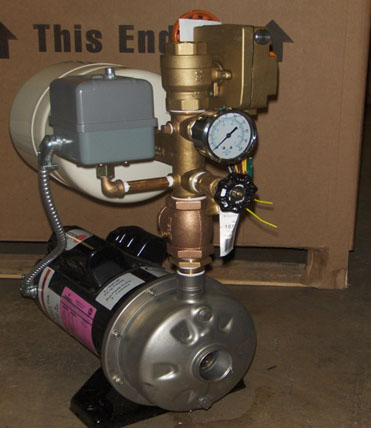

Centrifugal Transfer Pump Systems

Centrifugal pump systems are used to transfer liquids from sumps, pits, tanks and transfer stations.

These pumps come in a variety of horsepower and typically require 208-230/460 3 phase power. These pumps can be designed for low flow low head or high flow high head scenarios. Typical flow rates are 5-200 GPM with TDH ranges from 5-200. MAE2 can integrate centrifugal pumps as prepackages systems using common skid base, inlet and outlet pipe and fittings, instrumentation and local or remote control packages.

Pneumatic Pumping Systems

Pneumatic Free Product Recovery and Total Fluids Pumping Systems

Pneumatic submersible pumps, a type of downwell pump, are used to extract contaminated groundwater, leachate and free phase LNAPL and DNAPL. Each pump system uses air to displace the liquid and are safe in explosive hazardous locations. Pneumatic pump systems provide low to moderate flow rates typically from .5-8 GPM. MAE2 can provide turnkey pneumatic systems coupled with compressor, solenoids, level control, product drums, oil water separators and treatment packages.

Pneumatic Pump Water Treatment System

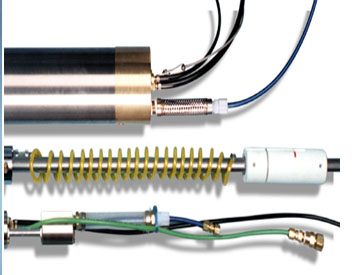

Electric Submersible Pumps

Electric submersible pumps,a type of downwell pump, are used to extracted groundwater and can be designed for low and high flow scenarios.

MAE2 can provide turnkey submersible pump packages with down well tubing, electrical cable, well head assemblies, instrumentation, valving and variable frequency drive controls packages.

Click to download MAE2 Electric Submersible Pumps data sheet

Liquid Ring Pump Systems

LRPs should be coupled with an inlet particulate filter-Integral seal oil reservoir with low oil level switch, coalescing air-oil separator element, pressure gauge, and sight glass air cooled seal oil heat exchanger with temperature control valve, high temperature switch and vacuum relief valve.